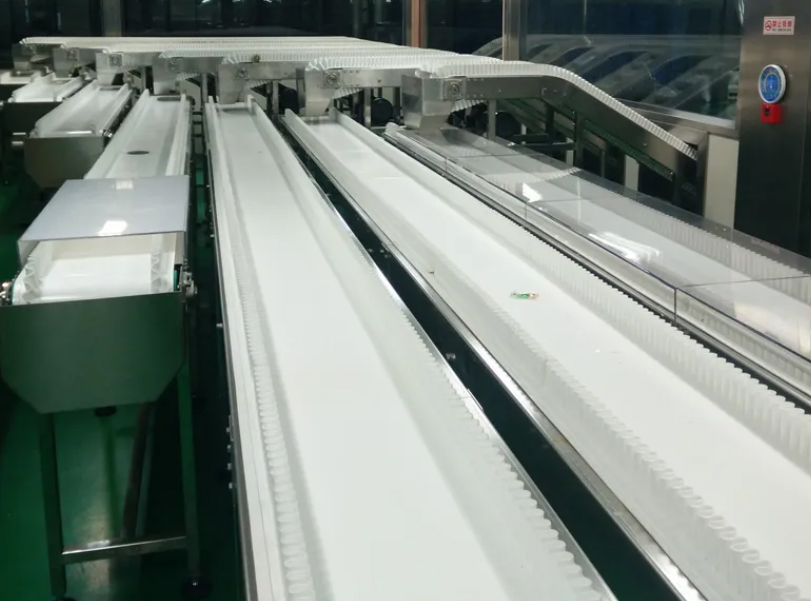

Belt Conveyor for Paper and Pulp Industry are crucial equipment in the paper and pulp industry, facilitating the efficient transport of materials within production facilities. These conveyors play a vital role in enhancing productivity, reducing manual handling, and ensuring smooth material flow. Let's explore the features, benefits, applications, and considerations related to belt conveyors in the paper and pulp industry.

Belt Material: Belts are typically made of durable materials like rubber, PVC, or fabric to withstand the demands of the industry.

Variable Speed: Adjustable speed settings to control the material flow as per production requirements.

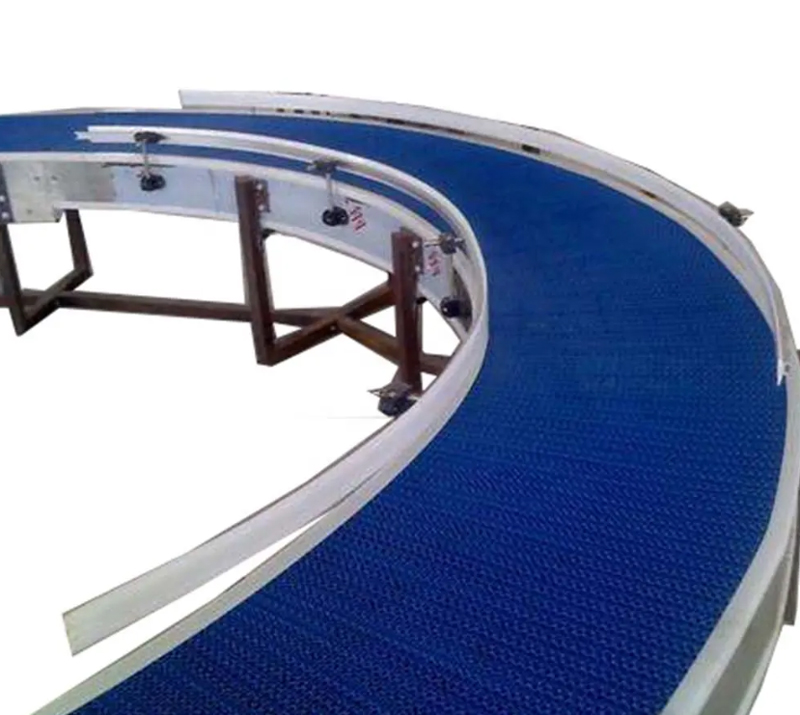

Customizable Design: Can be tailored to fit specific layouts and production processes in paper and pulp mills.

Safety Features: Equipped with safety guards, emergency stops, and sensors to ensure operator safety.

Automation Compatibility: Can be integrated with automation systems for seamless material handling.

Efficient Material Handling: Enables the continuous and efficient movement of raw materials, pulp, paper rolls, and finished products.

Labor Savings: Reduces manual handling, minimizing the risk of injuries and improving overall efficiency.

Space Optimization: Helps optimize floor space by moving materials vertically or horizontally as needed.

Product Protection: Gentle handling of delicate paper products to prevent damage during transport.

Cost-Effective: Reduces operational costs by streamlining material flow and improving productivity.

Raw Material Handling: Transports wood chips, pulp, and other raw materials to various processing units.

Pulp Processing: Moves pulp between different stages of the pulping process, such as pulping, bleaching, and drying.

Paper Production: Transfers paper rolls, sheets, and finished products between machines for cutting, printing, and packaging.

Waste Management: Conveys waste materials for recycling or disposal, contributing to sustainable practices in the industry.

Flat Belt Conveyors: Suitable for horizontal transport of materials within the facility.

Incline/Decline Belt Conveyors: Used for vertical movement of materials between different levels.

Troughed Belt Conveyors: Ideal for handling bulk materials and preventing spillage.

Portable Belt Conveyors: Mobile units that can be easily moved to different locations as needed.

Belt Conveyor for Paper and Pulp Industry are indispensable in the paper and pulp industry, providing a reliable and efficient means of material transport. By selecting the right type of conveyor, adhering to maintenance schedules, and ensuring safety measures are in place, paper and pulp manufacturers can streamline their operations, enhance productivity, and maintain a smooth material flow throughout the production process.