Inclined Belt Conveyor

Large inclination or vertical 90°conveying powder, block and other bulk materials, the use of corrugated sidewall conveyor belt can prevent materials from scattering and falling

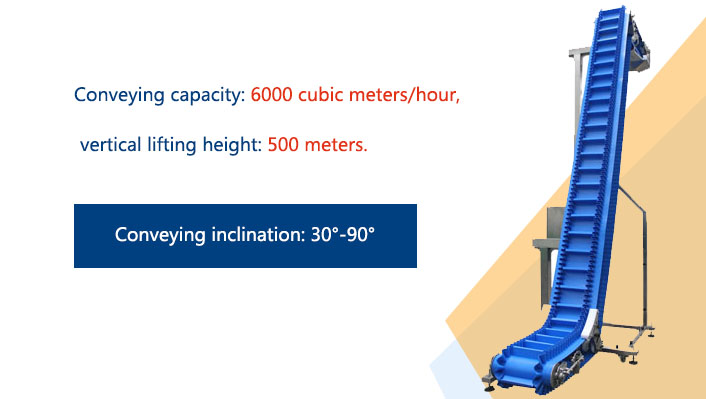

- Conveying angle: 0-90 degrees

- Conveying capacity: 6000 tons/hour

- Conveying height: 500 meters

- Suitable for powder, granular and pasty materials

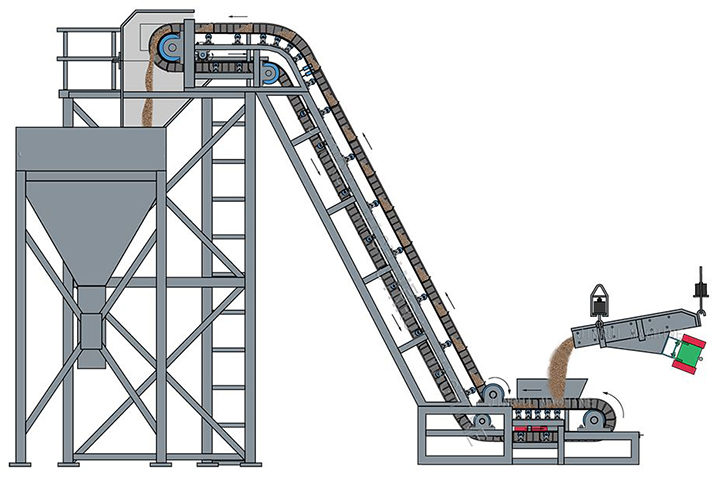

Inclined belt conveyor is used to transport bulk materials at large inclination angle or vertical 90°, which can solve the conveying angle that ordinary and patterned belt conveyors cannot reach. Inclined belt conveyor is a flat rubber conveyor belt glued with flexible rubber on both sides The corrugated vertical "skirt", and between the skirts, there is a certain strength and elasticity of the diaphragm to form a box-shaped bucket, which can prevent the material from falling.

Features and Benefits

1. The material is conveyed at an inclination angle of 0°-90°, which can effectively reduce the floor space.

2. It can convey 6000 cubic meters of powder, granular and small block or bulk materials per hour, and the conveying height can reach 500 meters;

3. The conveyor belt with corrugated sidewalls and diaphragms can avoid slipping and falling of materials when conveying at a large inclination angle.

Principle of Inclined Belt Conveyor

Inclined belt conveyor sticks free-stretching rubber corrugated vertical "skirts" on both sides of the flat rubber conveyor belt, and between the skirts there is a certain strength and elasticity of the diaphragm to form a box-shaped bucket, so that the material is in the bucket. continuous conveying.

Technical Parameters

| bandwidthB(mm) | 300 | 400 | 500 | 650 | 800 | |||||||||

| sidewall height(mm) | 40 | 60 | 60 | 80 | 80 | 120 | 120 | 160 | 120 | 160 | 200 | 240 | ||

| Partial conveying inclination conveying amountQ3/h | 30° | 15 | 14 | 20 | 34 | 46 | 71 | 104 | 120 | 128 | 157 | 195 | 235 | |

| 45° | 11 | 10 | 14 | 26 | 35 | 57 | 83 | 97 | 102 | 127 | 157 | 195 | ||

| 60° | 8 | 7 | 10 | 18 | 25 | 40 | 58 | 69 | 72 | 90 | 112 | 142 | ||

| 90° | 4 | 4 | 5 | 10 | 13 | 21 | 31 | 37 | 38 | 48 | 60 | 76 | ||

| Dimensions | Head wheel center heightH2/h(MM) | 350-100 | 1100-2000 | 1300-2000 | 1300-2000 | |||||||||

| Tail wheel center heightH2/h(MM) | 335 | 330-490 | 600 | 600 | 600-800 | |||||||||

| Middle section belt heightH2/h(MM) | 450 | 500-700 | 760-800 | 800-850 | 800-1115 | |||||||||

| Middle foot widthB2/h(MM) | 480 | 580 | 870 | 1020 | 1220 | |||||||||

| bandwidthB(mm) | 1000 | 1200 | 1400 | |||||||||||

| sidewall height(mm) | 120 | 160 | 200 | 240 | 160 | 200 | 240 | 300 | 160 | 200 | 240 | 300 | 400 | |

| Partial conveying inclination conveying amountQ3/h | 30° | 172 | 216 | 267 | 327 | 275 | 331 | 419 | 466 | 319 | 395 | 500 | 564 | 794 |

| 45° | 137 | 175 | 216 | 271 | 222 | 267 | 347 | 384 | 258 | 318 | 414 | 465 | 680 | |

| 60° | 96 | 124 | 153 | 197 | 158 | 190 | 253 | 178 | 184 | 226 | 302 | 337 | 524 | |

| 90° | 51 | 66 | 83 | 106 | 85 | 102 | 136 | 149 | 98 | 121 | 162 | 180 | 281 | |

| Dimensions | Head wheel center heightH2/h(MM) | 1400-2000 | 1600-2000 | |||||||||||

| Tail wheel center heightH2/h(MM) | 600-800 | 800-1000 | 800-1200 | |||||||||||

| Middle section belt heightH2/h(MM) | 800-1200 | 1050-1500 | 1050-1700 | |||||||||||

| Middle foot widthB2/h(MM) | 1440 | 1690 | 1890 | |||||||||||

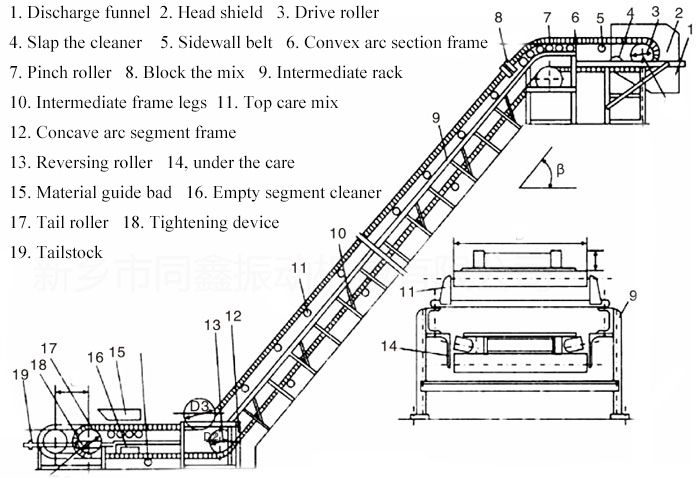

Inclined belt conveyor structure

Inclined belt conveyor is composed of corrugated sidewall conveyor belt, driving device, transmission roller, reversing roller, pinch roller, idler roller, idler roller, vertical roller, flapping wheel cleaning device, tensioning device and other parts.

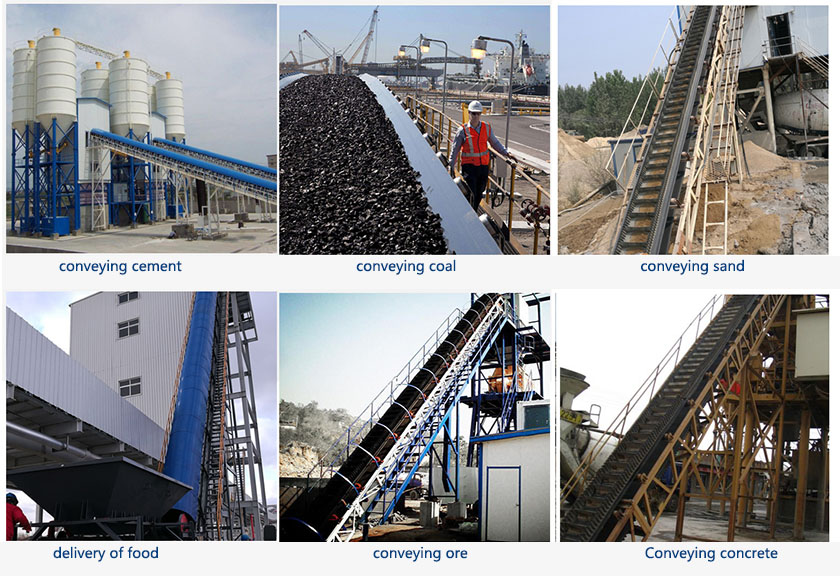

Application

Inclined belt conveyors are used in underground mining engineering, open-pit mining, large self-unloading ships, etc. The corrugated sidewall belt conveyor can transport various bulk materials in horizontal, inclined, vertical and variable-angle directions, such as: Coal, ore, sand, fertilizer and grain, etc. The particle size of the material can reach 400mm, and it is widely used in coal, metallurgy, construction, grain, chemical industry, electric power and other departments.

Customer case