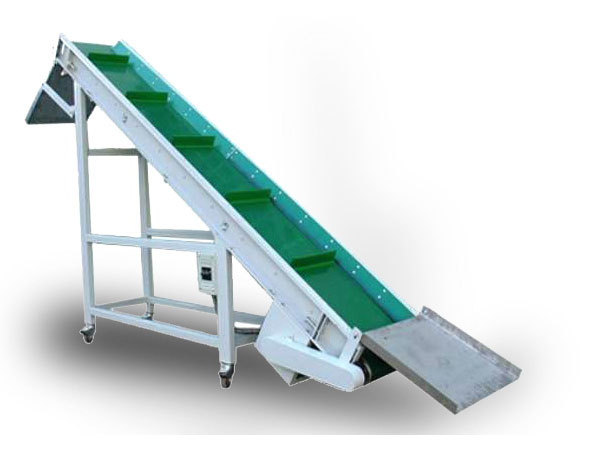

Grain Belt Conveyor

For short-distance transportation or loading and unloading of bulk materials in the grain industry

- Conveying capacity: 160 tons/hour

- Conveying height: 15 meters

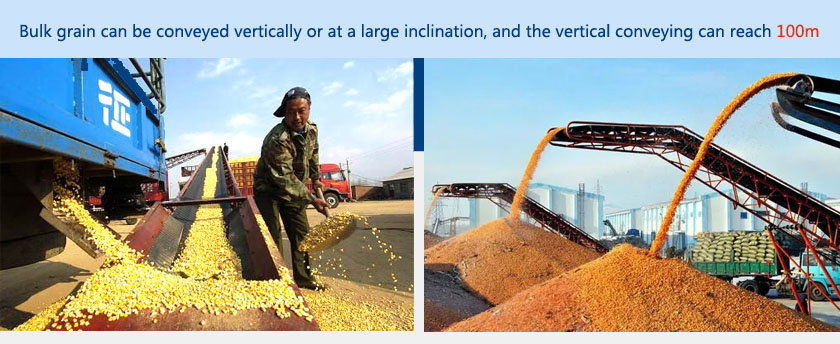

- Conveying angle: 0-90 degrees

Grain belt conveyors are often used for short-distance transportation such as grain transportation, loading, stacking, and storage in rural areas. They can load and unload bulk grain or bagged grain. They can also be used for bulk material storage in large and medium-sized grain warehouses. There are fixed and mobile types. The type grain conveyor is to install universal wheels or pneumatic tires at the bottom of the belt conveyor for occasions where the loading and unloading locations are changed.

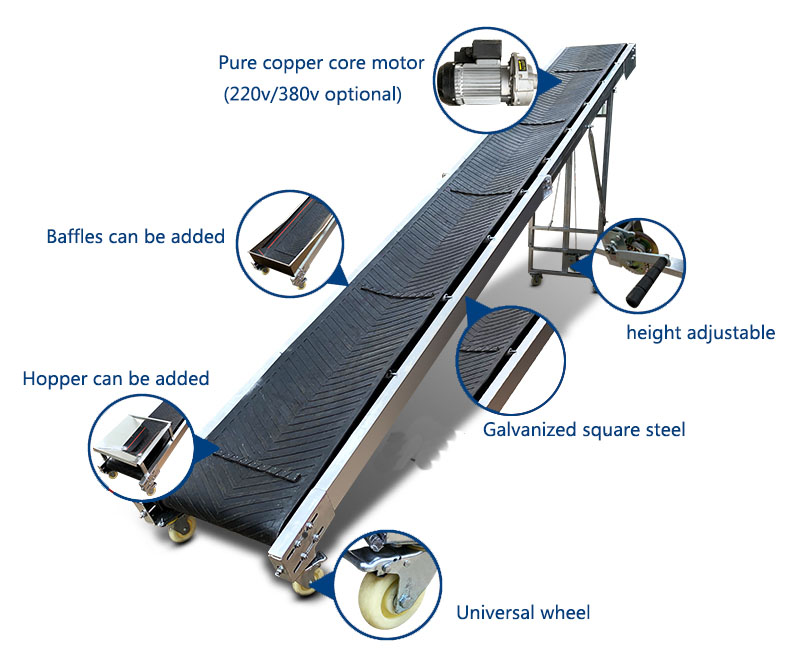

Features and Benefits

1. It can transport 160 tons of bulk materials per hour, and can transport a height of 15 meters;

2. There is no relative movement between the conveyor belt and the material, which will not cause wear on the conveyor belt, which can reduce the loss of the machine;

3. Universal wheels can be installed according to the requirements of the conveying environment and occasions to facilitate movement;

4. Grain belt conveyor can use conveyor belts of different materials according to the characteristics of materials to adapt to the transportation of materials of different natures.

Principle of Cleated belt conveyors

Cleated belt conveyors mainly use the conveyor belt as a traction member and a bearing member. When the cleated belt conveyors are started, the driving device drives the transmission roller, and the friction between the transmission roller and the conveyor belt drives the conveyor belt to run, and the grain is driven by the conveyor belt. to achieve the purpose of delivery.

Technical parameters

| Project | DY5051 | DY5071 | DY50101 | DY50102 | DY50102A | DY50151 | DY50152 | DY50152A | |

| Captain(m) | 5 | 7 | 10 | 10 | 10 | 15 | 15 | 15 | |

| Bandwidth(mm) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Belt speed(m/s) | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

| *large conveying height(m) | 1.63 | 1.59 | 1.77 | 4.52 | 4.52 | 1.61 | 6.32 | 6.32 | |

| Delivery capacity | m3>h | 160 | 160 | 160 | 125 | 125 | 160 | 125 | 125 |

| /h | 145 | 145 | 145 | 112 | 112 | 145 | 112 | 112 | |

| Tilt angle (degrees) | 13°59′ | 9°16′ | 6.5° | 10°~>22° | 10°~22° | 3.81° | 10°~22° | 10°~22° | |

| Electric drum | Model | DY1.4 | DY1.4 | DY1.4 | DY1.5 | DY1.3 | DY1.4 | DY1.6 | DY1.3 |

| Power KW | 2.2 | 2.2 | 2.2 | 3.0 | 1.1 | 2.2 | 4.0 | 1.1 | |

| Gross weight(kg) | 518 | 604 | 892 | 1126 | 1071 | 1225 | 1491 | 1491 | |

Grain belt conveyor structure

Grain belt conveyor is mainly composed of conveyor belt, driving device, braking device, supporting device, tensioning device, redirecting device, cleaning device, unloading device and other parts.

Sidewall: designed to be corrugated to prevent the material from slipping and falling.

Diaphragm: The main function is to support materials, which can be divided into two categories: fixed type and detachable type.

The ribs and the diaphragm are connected with the base tape by the method of secondary vulcanization, which has a high connection strength.

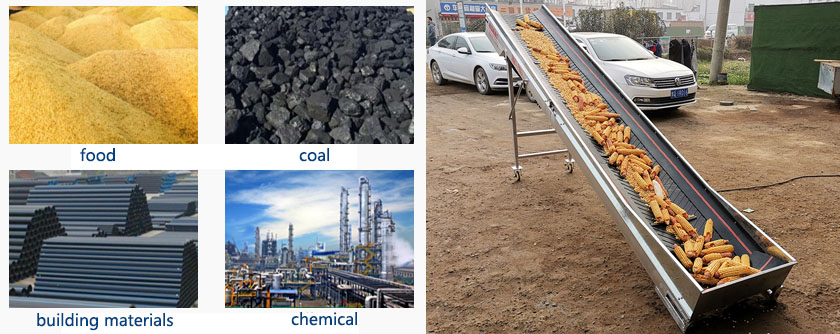

Application

Grain belt conveyor is specially used for grain industry. It is mainly used for grain bulk transportation, packaging conveyor for conveying, loading, palletizing, hoarding, and warehouse dumping, etc. It can be used in series or in conjunction with other conveying equipment. Grain conveyors with different bandwidths can be customized according to user requirements.

Customer site