Retractable Belt Conveyor

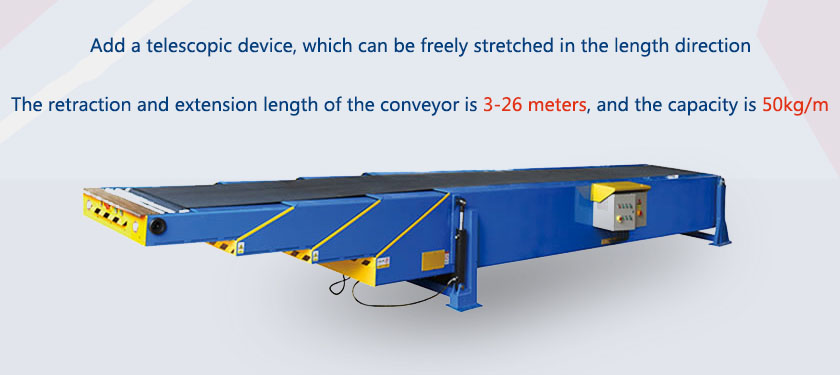

Conveying, telescopic, luffing, walking can be carried out synchronously, and the length of retraction and extension is between 3-26m- Fixed length: 3-26 meters

- Extension length: 2.8-14 meters (can be customized)

- Conveying speed: <30m/min

- Product Type: Mobile, Lift

What is Retractable Belt Conveyor?

Retractable Belt Conveyor (also known as telescopic loader) adds a belt storage device and a telescopic belt device. The belt can be retracted freely in the length direction through the operating lever or the operation button, and the length of the conveyor can be controlled at any time. The telescopic movement completes easy and efficient operation. Cargo handling.

Retractable Belt Conveyor automatically moves forward or backward from stack to stack, and the platform can be raised or lowered. Compared with ordinary belt conveyors, the transportation of goods on retractable belt conveyors uses height-adjustable self-elevating platforms, reducing reduce the physical burden and injury risk of employees.

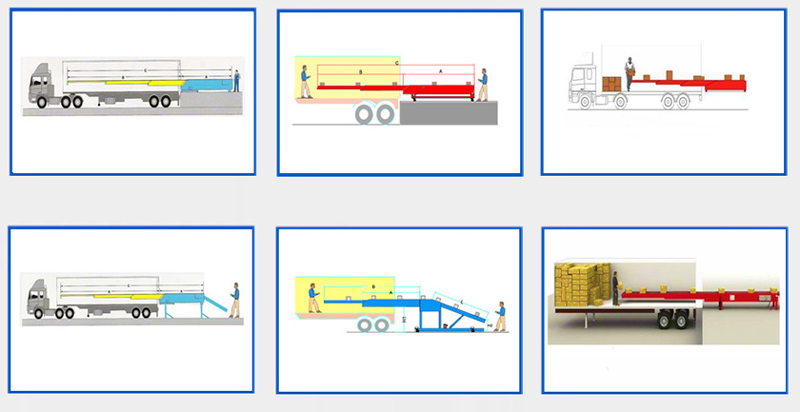

Retractable Belt Conveyor Application

The Retractable Belt Conveyor is mainly suitable for loading and unloading bagged goods of about 10-60 kg. Commonly used in ports, docks, stations, airports, warehouses, post and telecommunications, electrical appliances, light industry, food and other industries. Complete the transfer, loading and unloading of items or parts for raw materials entering the factory for production, assembly, finished product storage, and factory loading.

Retractable Belt Conveyor Features

Due to the unique telescopic, luffing and lateral traveling devices of the Retractable Belt Conveyor, the size of the equipment is reduced, the flexibility of the equipment is enhanced, and the accuracy and efficiency of the equipment are greatly improved.

1. The retracted and extended length of the conveyor ranges from 3 to 26 meters.

2. The front end of the equipment adopts a telescopic frame, which can not only adjust the position of the feeding point according to the user's requirements, but also realize the telescopic change during the conveying process to achieve the purpose of cloth distribution.

3. A luffing mechanism is added to the frame, and the height of the material drop point can be adjusted through the luffing during conveying, which reduces the dust of the material, avoids the breakage of the package, and improves the loading and unloading efficiency.

4. The bottom of the rack adopts a movable mechanism, which increases the flexibility of equipment movement.

5. Equipment conveying, stretching, luffing, and walking can be performed in a single operation or simultaneously.

6. The frame is directly bent by the whole steel plate, and the web parts on both sides are connected by bolts, which can avoid welding deformation and improve installation accuracy.

Retractable belt conveyor specifications

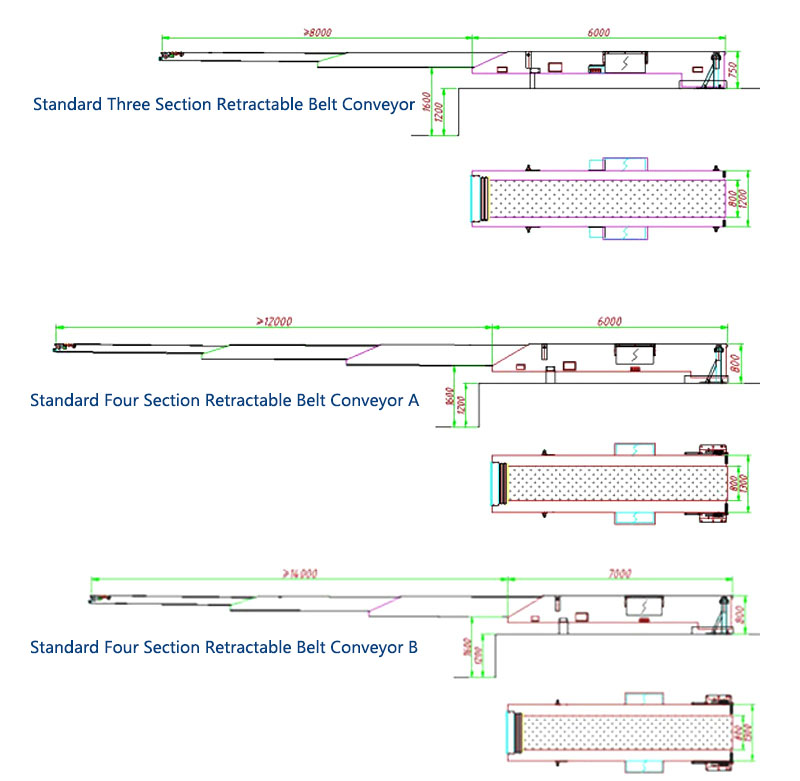

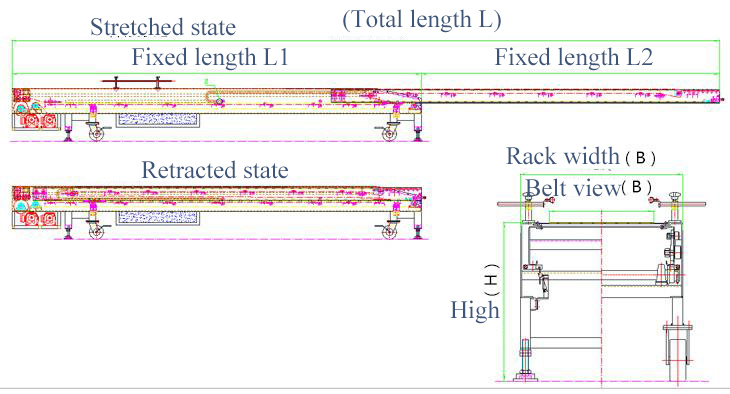

Conveyor sections: two-section, three-section, four-section. Width of conveyor belt: 500, 600, 700, 800, 1000, 1200mm. The telescopic belt conveying speed can be selected: fixed speed or variable speed. The belt conveying direction can be selected: one-way or two-way conveying materials. The belt conveying inclination can be selected: horizontal, fixed inclination or automatic lifting. The base of the fixed section of the conveyor can be selected: fixed or mobile. Conveying speed: <30m/min. Conveyor capacity: <70kg/m.

How the Retractable Belt Conveyor works

Retractable Belt Conveyor adds a telescopic mechanism to the ordinary belt conveyor, so that the belt conveyor can freely expand and contract in the length direction. Users can adjust the button according to their own requirements and control the length of the conveyor at any time. On models equipped with automatic lifting devices, the user can also control the height of the conveyor end at any time. Telescopic belt conveyors are mainly used in vehicle loading and unloading and material transmission systems with telescopic requirements. Telescopic belt conveyor, general belt conveyor, rope frame hanging belt conveyor, large inclination up and down belt conveyor, suitable for coal mine underground trough, roadway excavation uphill, downhill centralized transportation lane, main inclined shaft It is an ideal supporting equipment for coal mine mining mechanization for lifting, transportation of open-pit coal mines and ground transportation systems. The working environment is -10°C~+40°C.

Retractable Belt Conveyor Technical Parameters

| Model | Delivery volume (t/h) |

Bandwidth | Belt speed | Conveying length | Drum diameter | Idler diameter | Belt length | Tail length | Lap gauge | Installed power |

| DSJ65/20/2×30 | 200 | 650 | 1.63 | 600 | φ450 | φ89 | 50 | 12 | 900 | 2×30 |

| DSJ65/20/2×37 | 200 | 650 | 1.63 | 800 | φ450 | φ89 | 50 | 12 | 900 | 2×37 |

| DSJ65/10/40 | 100 | 650 | 2 | 600 | φ500 | φ89 | 100 | 12 | 900 | 40 |

| DSJ65/20/2×40 | 200 | 650 | 2 | 800 | φ500 | φ89 | 100 | 12 | 900 | 2×40 |

| DSJ65/20/2×55 | 200 | 650 | 2 | 1200 | φ500 | φ89 | 100 | 12 | 900 | 2×55 |

| DSJ80/30/2×30 | 300 | 800 | 1.63 | 500 | φ450 | φ89 | 50 | 12 | 1100 | 2×30 |

| DSJ80/40/40 | 400 | 800 | 2 | 250 | φ500 | φ89 | 100 | 12 | 1100 | 40 |

| DSJ80/40/2×40 | 400 | 800 | 2 | 500 | φ500 | φ89 | 100 | 12 | 1100 | 2×40 |

| DSJ80/40/2×40P | 400 | 800 | 2 | 500 | φ500 | φ89 | 100 | 12 | 1100 | 2×40 |

| DSJ80/40/2×55 | 400 | 800 | 2 | 700 | φ500 | φ89 | 100 | 12 | 1100 | 2×55 |

| DSJ80/50/2×75 | 500 | 800 | 2 | 800 | φ500 | φ89 | 50 | 12 | 1100 | 2×75 |

| DSJ80/40/2×90 | 400 | 1200 | 2 | 1200 | φ630 | φ89 | 50 | 12 | 1100 | 2×90 |

| DSJ80/40/2×110 | 500 | 800 | 2 | 1400 | φ630 | φ89 | 100 | 15 | 1100 | 2×110 |

| DSJ100/63/2×75 | 630 | 1000 | 2 | 650 | φ630 | φ108 | 50 | 12 | 1362 | 2×75 |

| DSJ100/63/125 | 630 | 1000 | 2 | 500 | φ630 | φ108 | 100 | 15 | 1362 | 125 |

| DSJ100/80/2×125 | 800 | 1000 | 2 | 900 | φ1000 | φ108 | 100 | 15 | 1362 | 2×125 |

| DSJ100/80/132 | 800 | 1000 | 3 | 900 | φ100 | φ108 | 100 | 15 | 1362 | 2×132 |

| DSJ100/80/2×160 | 800 | 1000 | 3.15 | 1100 | φ1000 | φ133 | 100 | 15 | 1362 | 2×126 |

| DSJ100/80/2×200 | 800 | 1000 | 3.15 | 1300 | φ1000 | φ133 | 130 | 15 | 1362 | 2×200 |

| DSJ100/80/2×250 | 800 | 1000 | 3.15 | 1700 | φ1000 | φ133 | 130 | 15 | 1362 | 2×250 |

| DSJ120/100/2×75 | 1000 | 1200 | 2 | 600 | φ630 | φ108 | 50 | 15 | 1562 | 2×75 |

| DSJ120/180/2×200 | 1800 | 1200 | 3.3 | 650 | φ1080 | φ133 | 130 | 15 | 1562 | 2×200 |

| DSJ120/200/3×250 | 2000 | 1200 | 3.3 | 1100 | φ1080 | φ133 | 130 | 15 | 1562 | 3×250 |

| DSJ120/150/2×315 | 1500 | 1200 | 3.3 | 1200 | φ1080 | φ133 | 130 | 15 | 1562 | 2×315 |

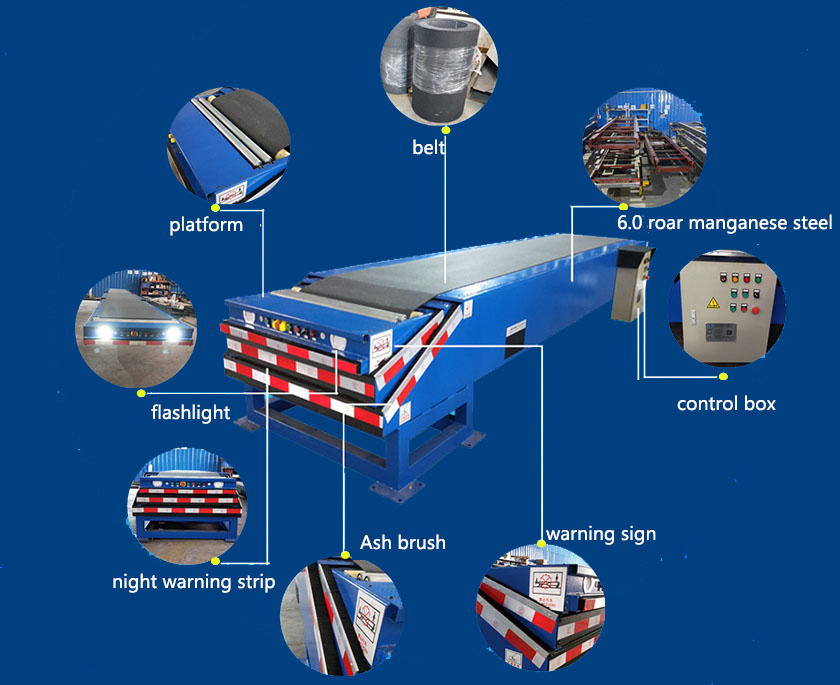

Retractable Belt Conveyor Structure

Retractable belt conveyor extension is divided into two parts: fixed part and non-fixed part. The fixed part is composed of a nose drive device, a belt storage device, and a retractable tape device;

Retractable Belt Conveyor Case