Fertilizer Plant PVC Sidewall Conveyor Belt is a specialized conveyor system designed to handle the unique challenges of transporting bulk materials, particularly fertilizers, in industrial settings. Fertilizer production involves the movement of granular or powdered materials, which can be abrasive, corrosive, and prone to spillage. The PVC sidewall conveyor belt is engineered to address these challenges, ensuring efficient and reliable material handling while minimizing downtime and maintenance costs.

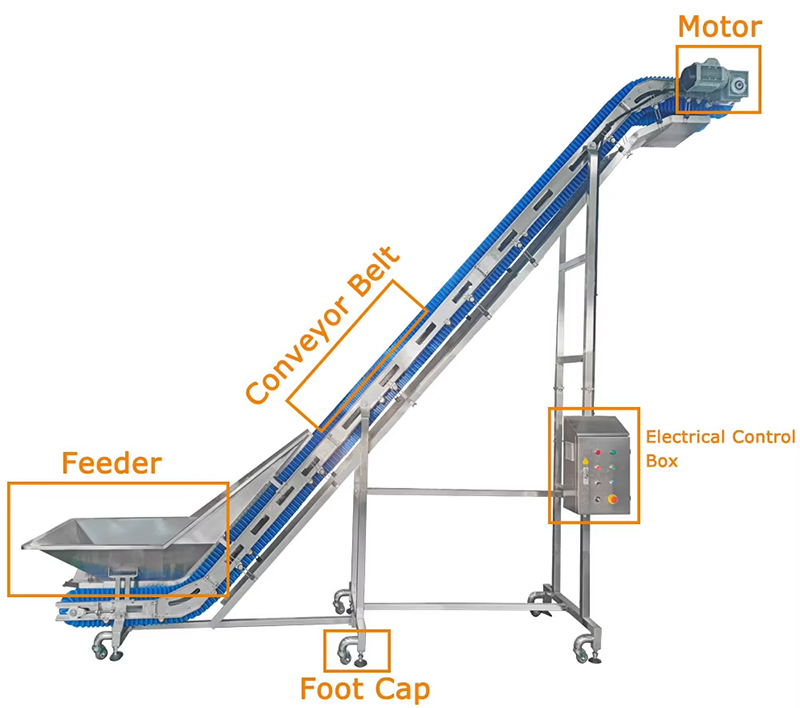

The PVC sidewall conveyor belt operates on the same principle as a standard conveyor belt, with the addition of vertical cleats that help contain materials and prevent spillage. The belt is driven by a motorized pulley system that moves the belt along the conveyor path, allowing for the efficient transport of materials within the fertilizer plant.

Enhanced Material Containment: The sidewalls on the conveyor belt prevent materials from falling off or spilling, ensuring efficient and reliable transportation.

Versatility: PVC sidewall conveyor belts can handle a wide range of materials, including fertilizers, chemicals, grains, and other bulk products.

Space-Saving Design: The vertical cleats allow for steep inclines and vertical lifts, maximizing space utilization in the plant.

PVC Material: The conveyor belt is made from polyvinyl chloride (PVC), a durable and flexible material that is resistant to abrasion, corrosion, and chemicals. PVC is particularly well-suited for fertilizer plants, where the materials being transported can be highly corrosive and abrasive.

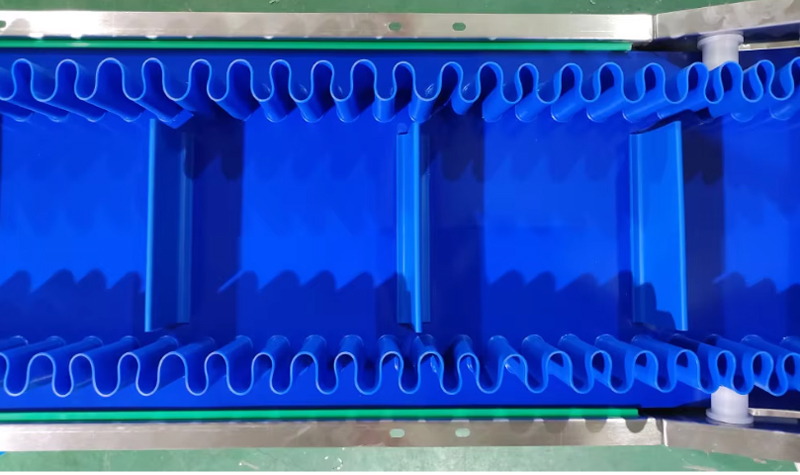

Sidewall Design: One of the standout features of this conveyor belt is its sidewall design. The sidewalls are integrated into the belt to prevent material spillage, especially when transporting materials on inclined or vertical conveyors. This design ensures that even fine or powdery fertilizers are contained within the belt, reducing waste and improving efficiency.

Cleats: The conveyor belt is equipped with cleats, which are raised sections that help to stabilize the material being transported. Cleats are particularly useful when conveying materials on steep inclines, as they prevent the material from sliding back. The height and spacing of the cleats can be customized based on the specific requirements of the fertilizer plant.

Transporting Bulk Materials: Conveying fertilizers, chemicals, and other bulk products between different processing units.

Loading and Unloading: Transferring materials to and from storage silos, trucks, and railcars.

Inclined Transport: Moving materials up steep inclines or vertically within the plant layout.

Process Integration: Integrating conveyor systems into various stages of the fertilizer production process for seamless material handling.

Fertilizer Plant PVC Sidewall Conveyor Belt is an essential component in the efficient and reliable transportation of materials within a fertilizer production facility. Its PVC construction, sidewall design, and cleats make it well-suited to handle the abrasive and corrosive nature of fertilizers, while its high tensile strength ensures durability under heavy loads. Whether used for raw material handling, granulation, finished product transportation, or waste management, this conveyor belt plays a crucial role in maintaining the efficiency and productivity of fertilizer plants. Its adaptability and low maintenance requirements make it a cost-effective solution for the demanding environment of fertilizer production.