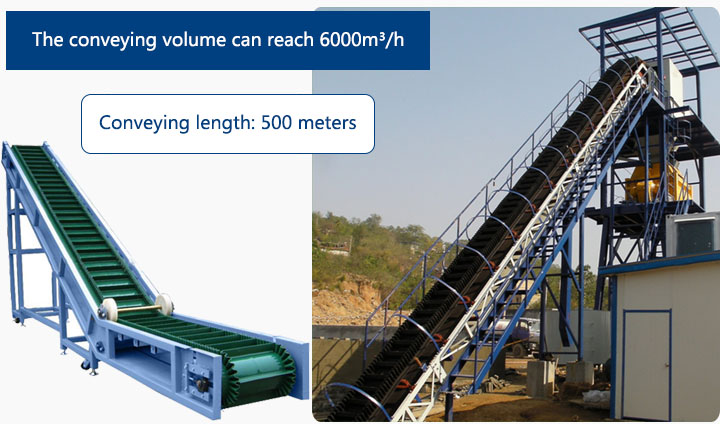

Cleated Belt Conveyors

Large inclination or vertical conveying of powder, block and other bulk materials

- Conveying capacity: 6000 tons/hour

- Conveying height: 500 meters

- Conveying angle: 30°-90°

Cleated belt conveyors video-conveying wood chips on site

Cleated belt conveyors use the form of skirt baffles on the conveyor belt, plus the reversing rollers, which can be made into an angle of 50-90 degrees, with the characteristics of large capacity and strong versatility.

FEATURES AND BENEFITS

1. It can transport bulk materials at a large inclination angle, which can save a lot of equipment floor space and completely solve the conveying angle that cannot be achieved by ordinary and patterned belt conveyors.

2. The mechanized belt conveyor conveys materials, and the overall investment cost is low, saving about 20% to 30% of the investment cost.

3. Large conveying capacity, up to 6000m3/h, vertical lifting height up to 500m, and material particle size up to 400mm. .

4. When the material is conveyed vertically, the maximum particle size of the material can reach 400mm.

5. Smooth transition from horizontal to inclined (or vertical).

Technical parameters

| bandwidthB(mm) | 300 | 400 | 500 | 650 | 800 | |||||||||

| sidewall height(mm) | 40 | 60 | 60 | 80 | 80 | 120 | 120 | 160 | 120 | 160 | 200 | 240 | ||

| Partial conveying inclination conveying amountQ3/h | 30° | 15 | 14 | 20 | 34 | 46 | 71 | 104 | 120 | 128 | 157 | 195 | 235 | |

| 45° | 11 | 10 | 14 | 26 | 35 | 57 | 83 | 97 | 102 | 127 | 157 | 195 | ||

| 60° | 8 | 7 | 10 | 18 | 25 | 40 | 58 | 69 | 72 | 90 | 112 | 142 | ||

| 90° | 4 | 4 | 5 | 10 | 13 | 21 | 31 | 37 | 38 | 48 | 60 | 76 | ||

| Dimensions | Head wheel center heightH2/h(MM) | 350-100 | 1100-2000 | 1300-2000 | 1300-2000 | |||||||||

| Tail wheel center heightH2/h(MM) | 335 | 330-490 | 600 | 600 | 600-800 | |||||||||

| Middle section belt heightH2/h(MM) | 450 | 500-700 | 760-800 | 800-850 | 800-1115 | |||||||||

| Middle foot widthB2/h(MM) | 480 | 580 | 870 | 1020 | 1220 | |||||||||

| bandwidthB(mm) | 1000 | 1200 | 1400 | |||||||||||

| sidewall height(mm) | 120 | 160 | 200 | 240 | 160 | 200 | 240 | 300 | 160 | 200 | 240 | 300 | 400 | |

| Partial conveying inclination conveying amountQ3/h | 30° | 172 | 216 | 267 | 327 | 275 | 331 | 419 | 466 | 319 | 395 | 500 | 564 | 794 |

| 45° | 137 | 175 | 216 | 271 | 222 | 267 | 347 | 384 | 258 | 318 | 414 | 465 | 680 | |

| 60° | 96 | 124 | 153 | 197 | 158 | 190 | 253 | 178 | 184 | 226 | 302 | 337 | 524 | |

| 90° | 51 | 66 | 83 | 106 | 85 | 102 | 136 | 149 | 98 | 121 | 162 | 180 | 281 | |

| Dimensions | Head wheel center heightH2/h(MM) | 1400-2000 | 1600-2000 | |||||||||||

| Tail wheel center heightH2/h(MM) | 600-800 | 800-1000 | 800-1200 | |||||||||||

| Middle section belt heightH2/h(MM) | 800-1200 | 1050-1500 | 1050-1700 | |||||||||||

| Middle foot widthB2/h(MM) | 1440 | 1690 | 1890 | |||||||||||

Cleated Belt Conveyors Structure

The structure of Cleated belt conveyors includes tailstock (with tensioning device), tailstock, sidewall conveyor belt, material guide trough, concave arc section bracket, pinch pulley, diverting wheel, intermediate frame, intermediate frame bracket, convex arc section bracket , Convex segment steering wheel, head frame, beater, head cover, drive roller (including power), and hopper.

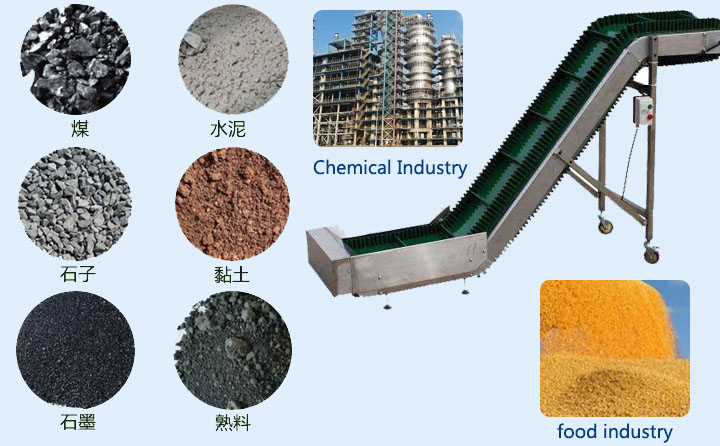

Application

Cleated belt conveyors are often used in coal, chemical industry, building materials, metallurgy, electric power, light industry, grain, port, ship and other industries, conveying a specific gravity of 0.5-2.5t in the working environment humidity range of -15℃--+40℃ /m3 of various bulk materials.

Customer site