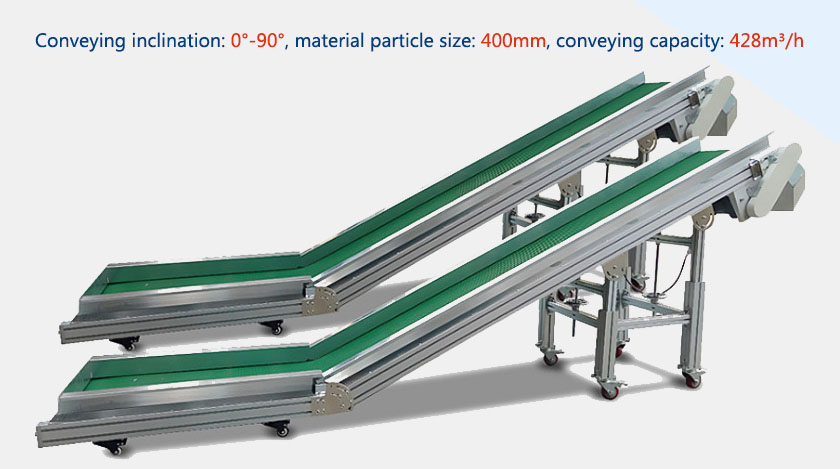

Climbing Belt Conveyor

0-90°climbing conveying, using corrugated sidewall + diaphragm conveyor belt to prevent material from falling, suitable for bulk materials with a bulk density of 0.8-3.5t/m³.

- Climbing angle: 0°-90°

- Conveying capacity: 428 cubic meters per hour

- Bandwidth: 100-1500mm

- Conveying distance: 203 meters

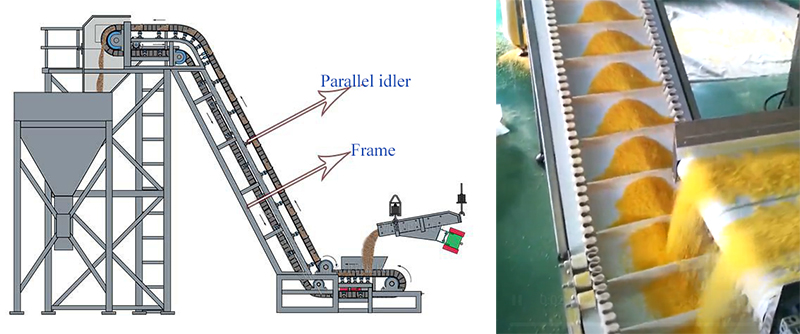

Climbing belt conveyor can be used for feeding and climbing conveying of various bulk materials. The conveying angle is 0°-90°. There are freely expandable rubber corrugated vertical "skirts" on both sides of the flat rubber conveyor belt. A transverse partition with a certain strength and elasticity is glued between them to form a box-shaped bucket, so that the material is kept in the bucket. For continuous conveying, the climbing belt conveyor is mainly used to convey materials of different heights, to achieve connection with other conveyors, and can be used for inclined or vertical conveying of powder and granular materials, and can be smoothly connected with roller conveyors or chain conveyors connection.

Climbing Belt Conveyor Application

Climbing belt conveyor is used for conveying under the condition of a certain slope. It is widely used in various industries such as coal, mining, building materials, chemical industry, boiler coal transportation, sand aggregate production line, port and metallurgy. The ambient temperature ranges from -19° to 40° to convey various bulk materials with a bulk density of 0.8-3.5t/3, such as: gravel, sand, quartz stone, coal, coke, raw coal, coal powder, soil clods, Materials with high density such as muck, fluorite, limestone, cement, etc.

Features and Benefits

1. It can transport bulk materials at a large inclination angle, which can save a lot of equipment floor space, completely solve the conveying angle that cannot be achieved by ordinary belt conveyors, and can transport within the range of 30°-90°.

2. The conveying capacity is large, up to 456m³/h, and the vertical lifting height can reach 203m. When the material is conveyed vertically, the particle size of the material can reach 400mm.

3. It can realize one or more feeding control, and it can be conveniently connected with various feeding equipment.

4. The conveyor belt with corrugated sidewalls and partitions can prevent materials from slipping when conveying at a large inclination angle.

5. The bearing surface is large, and baffles can be installed to avoid material leakage during conveying.

Climbing Belt Conveyor Principle

Climbing belt conveyor drives the drive roller through the reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase the traction force and facilitate dragging. When the material is fed from the feeding end of the belt conveyor, it falls on the rotating conveyor belt, and the friction of the conveyor belt drives the material to be conveyed on the belt, and finally transported to the unloading end for unloading, completing the entire conveying process.

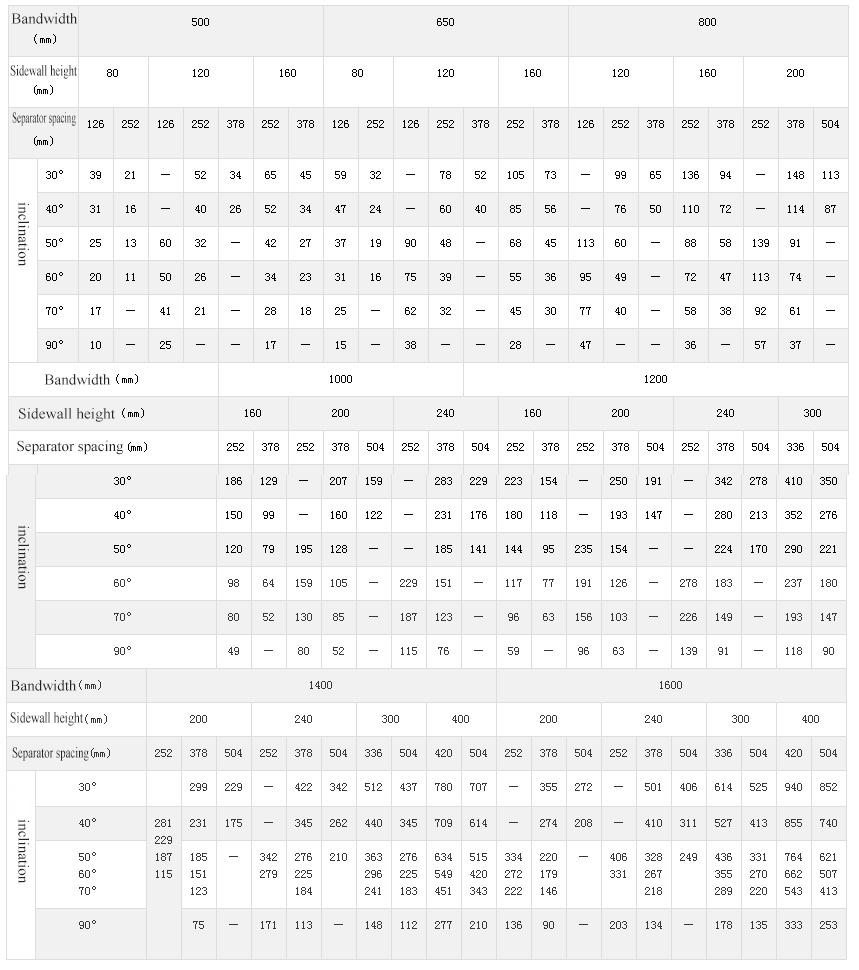

Technical Parameters

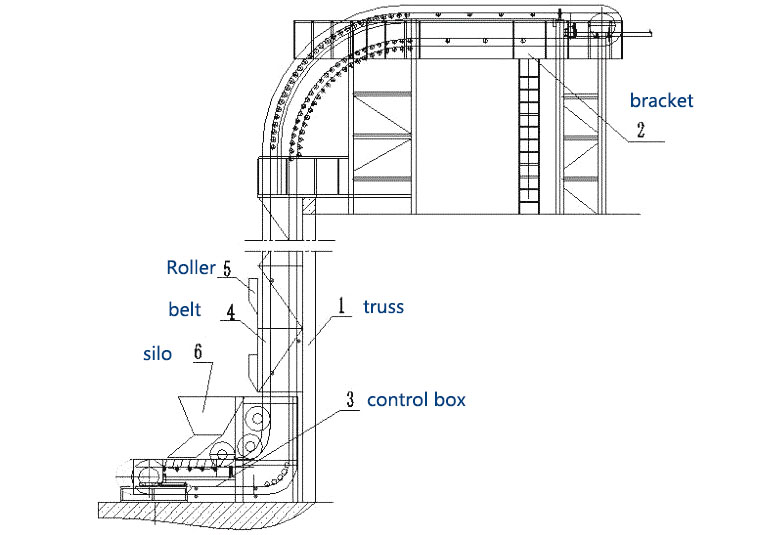

Climbing Belt Conveyor Structure

The climbing belt conveyor is mainly composed of a head frame, a pinch pulley, a transmission roller, a conveying belt, a driving pulley, a driven pulley, a pallet, an idler, a tensioning structure, a motor drive system, and an electrical control system.

Conveyor length: generally 1m, 2m, 3m, 4m, 6m, 10m, other sizes can be customized.

Belt wire rack material: carbon steel, stainless steel, aluminum profiles.

Conveyor belt: 2mm, 3mm, 5mm, thick PVC belts can be used, and PE, PU belts, and anti-static belts are also available.

Wire brackets are: stainless steel, aluminum profiles, carbon steel spray, etc.

Conveyor side waist: the bending height is generally 80mm, 100mm, 120mm, 160mm.

Conveyor legs: 4040, 4060.

Conveyor feet: adjustable feet, casters;

Conveyor pallet: one-piece and split type can be used, and the split type can be made of carbon steel galvanized sheet, stainless steel sheet, etc.

Bar skirt: optional heights of 20mm, 30mm, 40mm, 50mm, 60mm, etc.

Bar spacing: 100mm-1000mm range, other sizes can also be customized.

The conveying speed is generally: 0.1 ~ 10M/min; the speed can also be adjusted or fixed according to the needs of the user.