PVC Belt Conveyor

Using PVC material, it can transport loose materials with a density of 500-2500kg/m³ without high hygiene requirements

- Conveying length: 103 meters

- Conveying capacity: 3000 tons/hour

- Conveying speed 10~60m/min

- Conveyor belt material: PVC

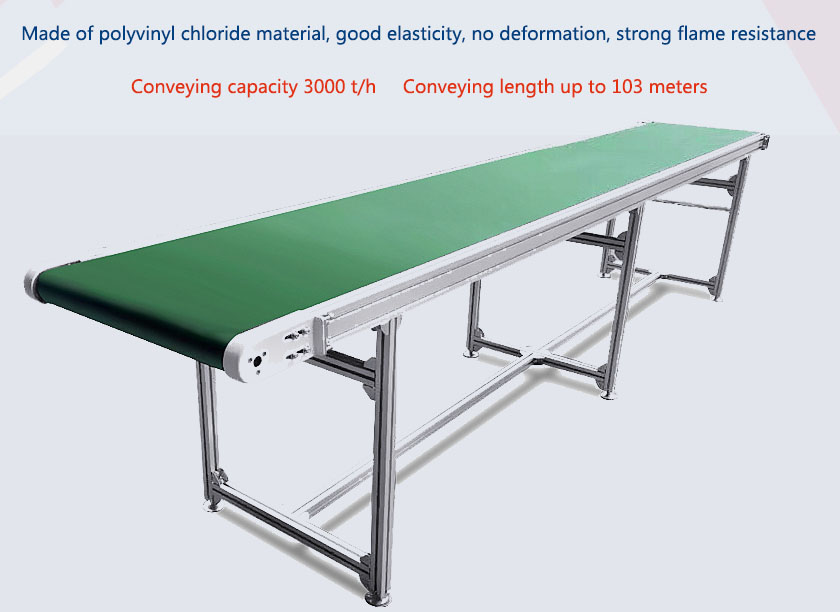

PVC belt conveyor means that the conveyor belt is made of polyvinyl chloride (polyvinyl chloride is composed of polyester fiber cloth and polyvinyl chloride glue), which has the characteristics of non-flammability, high strength, good elasticity, and not easy to deform.

PVC Belt Conveyor Model

PVC belt conveyor has fixed, mobile, large inclination, climbing and other models, and accessories such as lifting baffles and skirts can be added to the conveyor belt.

Features and Benefits

1. It is made of polyvinyl chloride, which has good elasticity, is not easy to deform, and has strong flame resistance.

2. It is suitable for conveying bulk materials or finished articles with a bulk density of 500~2500kg/m³ horizontally or at a large inclination angle.

3. The conveying capacity can reach 3,000 tons per hour, 103 meters can be conveyed, and the conveying speed is 10-60 m/min;

4. The main conveying forms are: trough belt conveying type and flat belt conveying type.

Technical Parameters

| bandwidthB(mm) | 300 | 400 | 500 | 650 | 800 | |||||||||

| sidewall height(mm) | 40 | 60 | 60 | 80 | 80 | 120 | 120 | 160 | 120 | 160 | 200 | 240 | ||

| Partial conveying inclination conveying amountQ3/h | 30° | 15 | 14 | 20 | 34 | 46 | 71 | 104 | 120 | 128 | 157 | 195 | 235 | |

| 45° | 11 | 10 | 14 | 26 | 35 | 57 | 83 | 97 | 102 | 127 | 157 | 195 | ||

| 60° | 8 | 7 | 10 | 18 | 25 | 40 | 58 | 69 | 72 | 90 | 112 | 142 | ||

| 90° | 4 | 4 | 5 | 10 | 13 | 21 | 31 | 37 | 38 | 48 | 60 | 76 | ||

| Dimensions | Head wheel center heightH2/h(MM) | 350-100 | 1100-2000 | 1300-2000 | 1300-2000 | |||||||||

| Tail wheel center heightH2/h(MM) | 335 | 330-490 | 600 | 600 | 600-800 | |||||||||

| Middle section belt heightH2/h(MM) | 450 | 500-700 | 760-800 | 800-850 | 800-1115 | |||||||||

| Middle foot widthB2/h(MM) | 480 | 580 | 870 | 1020 | 1220 | |||||||||

| bandwidthB(mm) | 1000 | 1200 | 1400 | |||||||||||

| sidewall height(mm) | 120 | 160 | 200 | 240 | 160 | 200 | 240 | 300 | 160 | 200 | 240 | 300 | 400 | |

| Partial conveying inclination conveying amountQ3/h | 30° | 172 | 216 | 267 | 327 | 275 | 331 | 419 | 466 | 319 | 395 | 500 | 564 | 794 |

| 45° | 137 | 175 | 216 | 271 | 222 | 267 | 347 | 384 | 258 | 318 | 414 | 465 | 680 | |

| 60° | 96 | 124 | 153 | 197 | 158 | 190 | 253 | 178 | 184 | 226 | 302 | 337 | 524 | |

| 90° | 51 | 66 | 83 | 106 | 85 | 102 | 136 | 149 | 98 | 121 | 162 | 180 | 281 | |

| Dimensions | Head wheel center heightH2/h(MM) | 1400-2000 | 1600-2000 | |||||||||||

| Tail wheel center heightH2/h(MM) | 600-800 | 800-1000 | 800-1200 | |||||||||||

| Middle section belt heightH2/h(MM) | 800-1200 | 1050-1500 | 1050-1700 | |||||||||||

| Middle foot widthB2/h(MM) | 1440 | 1690 | 1890 | |||||||||||

Structure diagram of PVC belt conveyor

PVC belt conveyor consists of frame, drive roller, redirecting roller, conveyor belt, tensioning device, driving device, idler and other parts.

Selection

1.The main conveying forms are: trough belt conveying type and flat belt conveying type.

2.The driving forms are: electric drum driving form and motor driving conveying form.

3.Material of conveyor belt: PVC conveyor belt, canvas belt, food belt, etc.

4.The forms of conveyor belts are: conveyor belts with baffles, hoardings and flat belts.

5.Wire brackets are: stainless steel, aluminum profiles, carbon steel spray, etc.

Application

PVC belt conveyor can be used in industries with low hygiene requirements, such as light industry, electronics, food, chemical industry, wood industry, hardware, mining, machinery and other industries. The temperature range of PVC conveyor belt products can be divided into: cold-resistant conveyor belt (-40℃ ), normal temperature conveyor belt (-10℃~+80℃).