Chain driven roller conveyors are common material conveying equipment and are widely used in industrial production and logistics transportation fields. It transports materials from the starting point to the target location through the rotation of the chain drive drum.

Chain driven roller conveyors have a wide range of application scenarios in various industries. Here are some common application scenarios:

Mines and Quarry: Used to transport ore, coal, sand and gravel from mining areas to crushers, screening equipment or stockpiling areas.

Building materials industry: used to transport cement, sand, bricks, concrete and other materials. These materials can be transported from the production line to the storage area or loading area.

Metallurgy and steel industry: used to transport raw materials such as iron ore, coke, limestone, or transport finished steel products from production lines to warehouses or loading areas.

Chemical industry: used to transport powdery or granular chemical raw materials, plastic granules, fertilizers, etc., from the production line to the storage bin or packaging area.

Grain processing and agriculture: Used to transport agricultural products such as grains, feed, seeds, etc., from warehouses or production lines to packaging areas or transport vehicles.

Logistics warehousing: used for loading, unloading and sorting of goods, which can be transported from warehouses or production lines to trucks or other storage equipment.

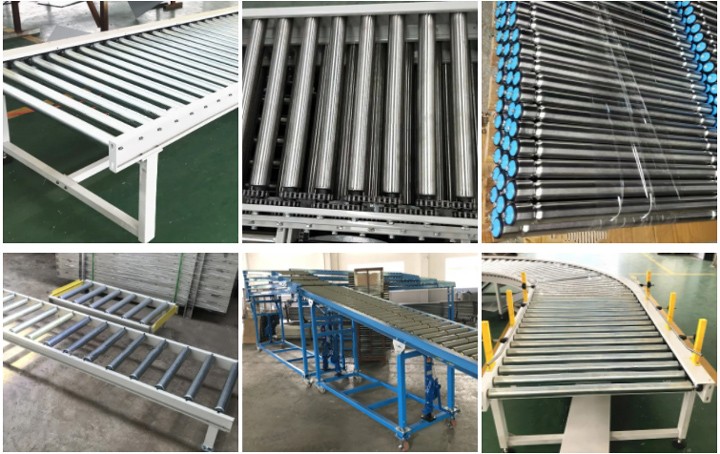

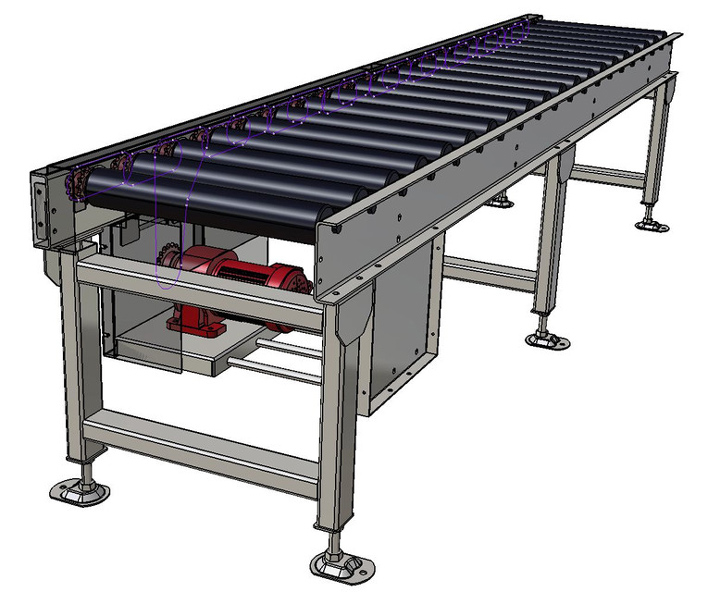

The conveyor is mainly composed of a conveying roller, a chain drive, a support frame and a motor. Conveying rollers are usually made of metal, plastic or rubber and have strong load-bearing capacity and wear resistance. The chain drive device is composed of a chain, a sprocket and a transmission shaft. The chain is driven by the motor, which in turn drives the drum to rotate.

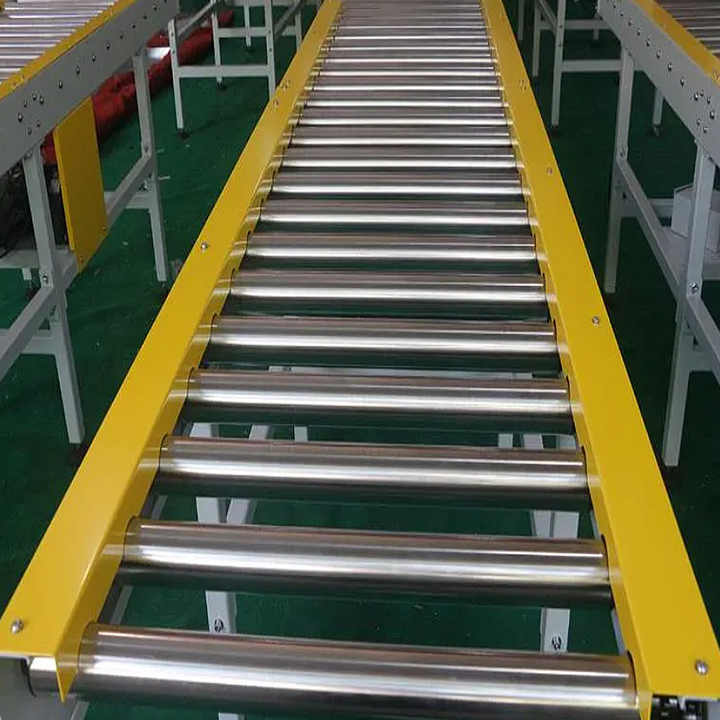

When working, the material is placed on the conveying roller, and with the movement of the chain, the roller begins to rotate, pushing the material forward. The surface of the conveying roller usually has raised grooves or rubber strips to improve the grip of the material and prevent slipping and leakage. The speed of the conveying roller can be adjusted as needed to adapt to the conveying requirements of different materials.

First of all, it is suitable for conveying various materials, including granular, lump, powder and liquid materials. Secondly, due to the reliability and stability of the chain drive, the conveyor can carry larger material loads and conveying distances. In addition, chain driven roller conveyors also have the characteristics of simple structure, easy maintenance, and long service life.

Mining industry: A large iron ore mine uses chain driven roller conveyors to transport ore from the mining area to crushers and screening equipment, improving production efficiency and material handling capabilities.

Building materials industry: A concrete production company uses chain driven roller conveyors to transport concrete from the mixing station to the construction site, reducing the cost of handling manpower and time.

Food processing industry: A flour processing plant uses chain driven roller conveyors to transport flour from the production line to the packaging area, achieving efficient flour transportation and precise discharge.

In short, chain driven roller conveyors are reliable and efficient material conveying equipment. Through the rotation of chain driven rollers, materials can be smoothly conveyed. They are widely used in material transportation and processing in various fields.