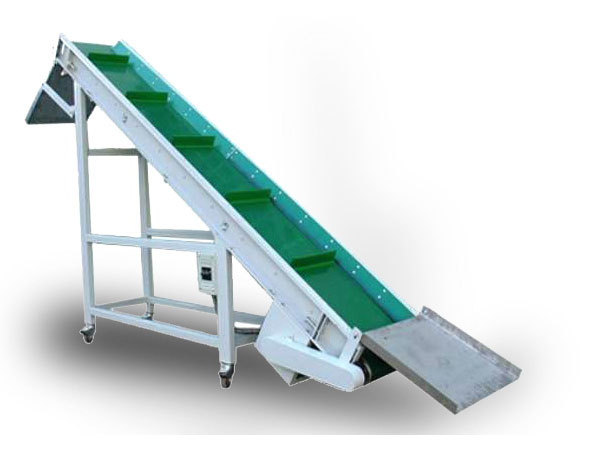

Mobile Conveyor Belt

For places where loading and unloading locations change frequently

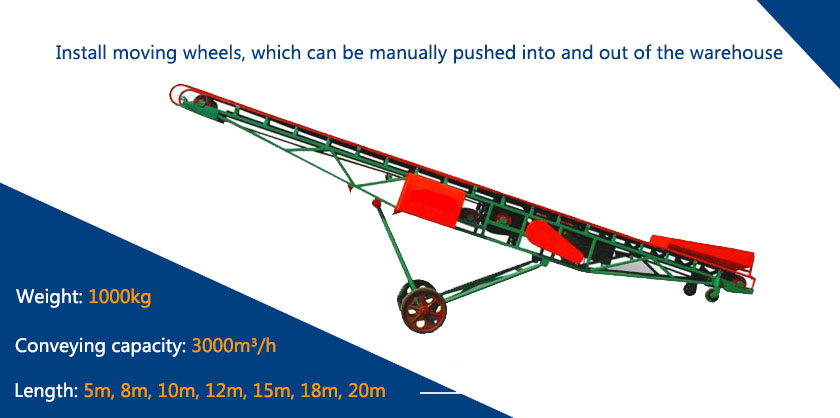

- Conveying capacity: 70-278 cubic meters per hour

- Conveying length: 5-20 meters

- Conveyor belt speed: 0.8-1.6 m/s

- Type: Electric and Manual Lift

Mobile conveyor belts are used for short-distance transportation and loading of bulk materials or finished products weighing less than 100 kg. Mobile belt conveyors can be divided into two types: elevating and non-elevating. The operation of the conveyor belt is driven by the electric drum, and the lifting and operation of the whole machine are non-motorized.

Mobile conveyor belt model

Mobile conveyor belt can be divided into two types: mobile adjustable belt conveyor and mobile retractable belt conveyor:

1. Mobile adjustable belt conveyor: The height can be adjusted within the specified height.

Lifting height of 6m: 1.7-2.7m, Lifting height of 8m: 2.5-3.7m, Lifting height of 10m: 2-4m, Lifting height of 12m: 2-4.5m, Lifting height of 15m: 3-6 meters

2. Mobile retractable belt conveyor: It can freely expand and contract in the length direction.

The number of conveyor sections: two-section, three-section, four-section, the retraction and extension length range is 3-26 meters (can be customized).

Features and Benefits

1. Free movement: with the addition of universal wheels, it can be moved to any place and adapt to more working conditions.

2. Downward conveying: It can be designed for downward conveying according to the user's conveying direction, which can be used for unloading. It is generally used when unloading bagged materials, and the conveying volume can reach 160 tons per hour.

3. Height adjustable: The lifting height can be adjusted according to the actual needs, and the electric control box is used to adjust the equipment to realize the automation of the equipment, avoid manual operation, and save manpower and material resources.

4. No material scattering: The rear of the fuselage is equipped with a guide groove and a baffle, and a guide groove and a baffle are installed at the tail to avoid falling material during feeding, and the design is more reasonable and humanized.

5. According to the environment and conditions, the movable wheel can be replaced with a pneumatic tire, which is convenient for users and prevents the ground from being crushed.

Working principle of mobile conveyor belt

The mobile belt conveyor is mainly composed of two end drums and closed conveyor belts which are tightly sleeved on them. The drum that drives the conveyor belt to rotate is called driving drum (driving drum); the other drum that only changes the direction of the conveyor belt movement is called changing drum. The driving drum is driven by a motor through a reducer, and the conveyor belt is driven by the friction force between the driving drum and the conveyor belt. The driving drum is usually installed at the unloading end to increase the traction force, which is conducive to dragging. The material is fed by the feeding end and falls on the rotating conveyor belt. It is driven by the friction of the conveyor belt and discharged at the discharging end.

Technical parameters

|

Width (mm) |

Conveying length(m) Power(kw) |

Transfer speed (m/s) |

Delivery volume (t/h) |

||

| 400 |

≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 | 30-60 |

| 500 |

≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 | 40-80 |

| 650 |

≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 | 80-120 |

| 800 |

≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 | 120-200 |

| 1000 |

≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 | 200-320 |

| 1200 |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 | 290-480 |

| 1400 |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 | 400-680 |

| 1600 |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 | 600-1080 |

| 1800 |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 | 800-1500 |

| 2000 |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 | 1000-2000 |

| 2400 |

≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 | 1500-3000 |

Mobile conveyor belt structure

Mobile conveyor belt is composed of solid tires, casters, driving devices, conveyor belts, idlers, tensioning devices, rollers and redirecting devices.

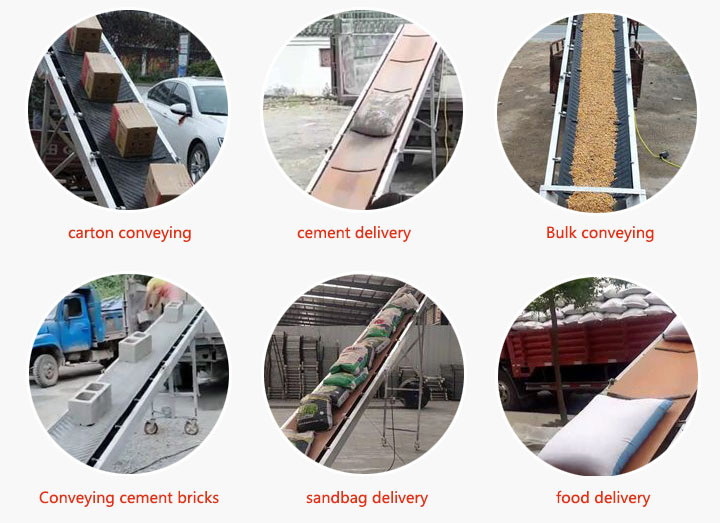

Application

Mobile conveyor belts are mainly used in ports, docks, stations, coal yards, warehouses, construction sites, sand and gravel yards, farms and other places where loading and unloading locations frequently change, for short-distance transportation and loading and unloading operations. Unload bulk materials or single items weighing less than 100kg and can be enclosed to protect from rain if required.

Customer case

Mobile conveyor belt manufacturers