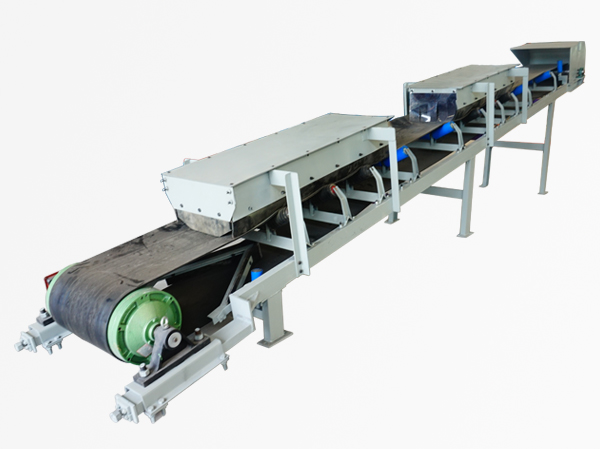

The belt conveyor is a widely used conveying equipment. It can be seen in almost every type of conveyor line in various industries. In the process of material transportation, the belt conveyor plays a big role, then the belt conveyor What are the components of the machine? Let's take the Xinxiang Dahan belt conveyor as an example to introduce you:

The belt conveyor is mainly composed of a driving device, a rolling device, a tensioning device, a roller portion, a cleaning portion, a discharging portion, a braking portion and the like. What role do these parts play in the belt conveyor?

Drive part: It consists of the motor, high-speed coupling, reducer and deceleration coupling on the base welded by the steel. According to the layout requirements: the drive unit is available in left and right mounts.

Function: The traction roller transmits the traction force to the conveyor belt by friction to move and transport the cargo.

Rolling part: two types of sub-drive roller and reversing roller.

Function:change the direction of movement of the conveyor belt.

Tensioning device: The tensioning device mainly has a screw type, a trolley weight type and a vertical weight type.

Function: Keep the conveyor belt with the necessary initial tension to avoid slipping on the drive roller and ensure that the sag of the conveyor belt between the two rollers is within the specified range.

Roller parts: slotted, parallel, self-aligning and cushioning rollers.

Function: Support the conveyor belt and the material on the belt to reduce the sag of the conveyor belt, so that it can run stably.

Cleaning section: Split spring cleaner and empty section cleaner.

Function: Keep the conveyor belt clean, ensure that the conveyor belt has sufficient friction on the transmission roller, prevent the conveyor belt from slipping and the conveyor belt deviation, effectively reduce the viscosity, the large material wear on the conveyor belt and the roller, and effectively extend the conveyor belt. , the service life of the roller.

Unloading part: divided into fixed plow type unloader and electric unloader.

Braking part: There are two types of belt backstop and roller backstop. The belt type backstop has a simple structure and a low cost, and is suitable for an ascending conveyor with an inclination angle of ≤18°. The roller backstop can be mounted on the low speed shaft of the reducer. It has a compact structure, the brake is stable and reliable, and has been serialized, and can be selected according to the reducer, and the use is more common, the maximum braking torque can reach 48. 5kN. m.

Function: When stopping, in order to prevent the conveyor belt of the inclined upward direction from moving under the action of the cargo weight, causing the material to reverse, the brake device should be provided at the driving device according to the specific situation.

Xinxiang Dahan is a professional manufacturer of conveying equipment. We have professional technical engineers and advanced equipment. We stand at the user's point of view and set reasonable price adjustments. Welcome to consult us!