Rubber conveyor belt

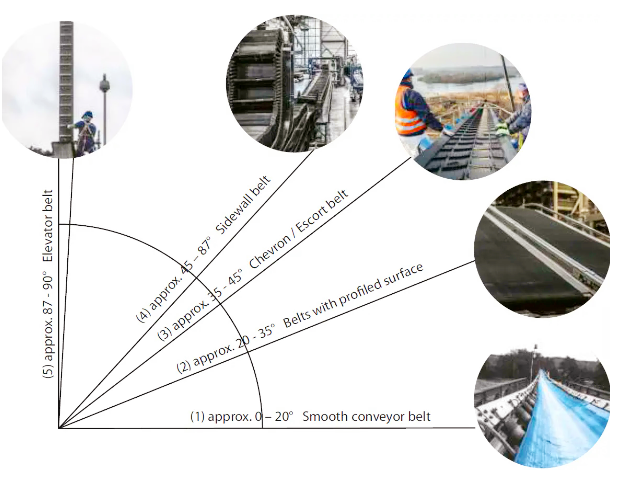

Rubber conveyor belt is a continuous conveying equipment with multi-layer rubber and fiber as the core structure. It is widely used in mining, building materials, ports, electric power, chemical industry and other industries. It is suitable for horizontal or inclined conveying of block, granular and powdery materials.

Belt width: 400/500/650/600/800/1000/1200/1500mm

Conveying length: 10-30 meters

Conveying capacity: 30-3000t/h

Conveying speed: 1.25-2.0m/s

Promise: Free shipping/5-day delivery/30-day return and exchange/customization support

What is a rubber conveyor belt?

Rubber conveyor belt is a continuously moving belt made primarily of rubber or rubber-like material used to transport goods, materials or items from one place to another in a variety of industries. These belts are widely used due to their durability, flexibility and ability to withstand a wide range of loads and environmental conditions. They are usually constructed of a multi-layer structure, including a rubber outer layer for protection and a fabric or steel cord core for strength and stability.

Video of rubber conveyor belts

What are the different types of rubber conveyor belts?

①Single-ply textile rubber conveyor belts

Construction: Excellent resistance to bending fatigue, impact and shock resistance, and excellent grooving properties.

Features: Single-ply carcass provides tension in excess of 2000kN/m. Low elongation allows for short take-up strokes.

Purpose: Single-ply textile rubber conveyor belts are developed to withstand the most demanding conditions and heavy industrial use, conveying large amounts of material.

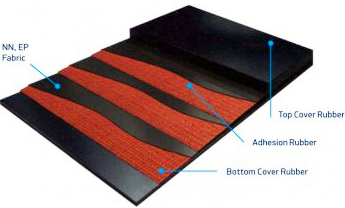

②Multi-layer textile rubber conveyor belt

Structure: Multi-layer textile rubber conveyor belt consists of cloth cover layer, carcass cover layer and degreased cloth

Features: It adopts a unique rubber mixture, which has the advantages of wear resistance, high temperature resistance, cold resistance, acid resistance and fuel resistance.

Applicable scenarios: Suitable for high tensile strength and long-distance transportation.

|

Type |

Picture |

Features |

Applicable scenarios |

|

Chemical corrosion resistant textile rubber conveyor belt |

|

Rubber design, and can withstand a variety of chemicals |

Conveying acidic and alkaline materials in chemical plants, fertilizer plants, pulp and paper mills and other industrial and mining enterprises |

|

Cold resistant textile rubber conveyor belt |

|

Low temperature resistant rubber layer |

Outdoor transportation of materials in cold areas, used to transport materials to cold storage |

|

Fire resistant textile rubber conveyor belt |

|

Fireproof performance |

Thermal power stations, mining, coal cleaning and other industries |

|

Food safety textile rubber conveyor belt |

|

Anti-tear and impact protection |

Food transportation and transportation of heavy materials |

|

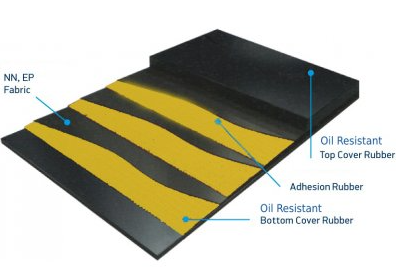

Oil resistant textile rubber conveyor belt |

|

Made of synthetic oil resistant rubber, which can reduce wear |

Parts coated with machine oil, heavy coal handling carbon in coking plants and power stations |

|

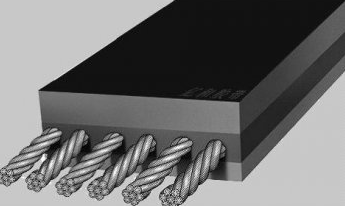

Wire rope rubber conveyor belt |

|

Bending fatigue resistance |

Long-distance, high-load, high-resistance cargo transportation |

The difference between rubber conveyor belt and other conveyor belts

|

Comparison items |

Rubber conveyor belt |

PVC/PU conveyor belt |

Metal conveyor belt |

|

Temperature resistance |

-10℃~200℃ (heat-resistant type) |

-10℃~80℃ |

≤800℃ (stainless steel) |

|

Wear resistance |

Excellent (covering rubber can be replaced) |

Medium |

Excellent |

|

Cost |

Medium |

Low |

High |

|

Applicable scenarios |

Heavy load, complex environment (mines, ports) |

Light load, food/electronics industry |

High temperature, corrosive environment |

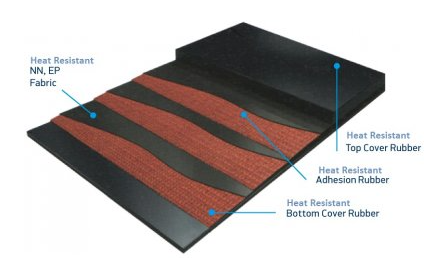

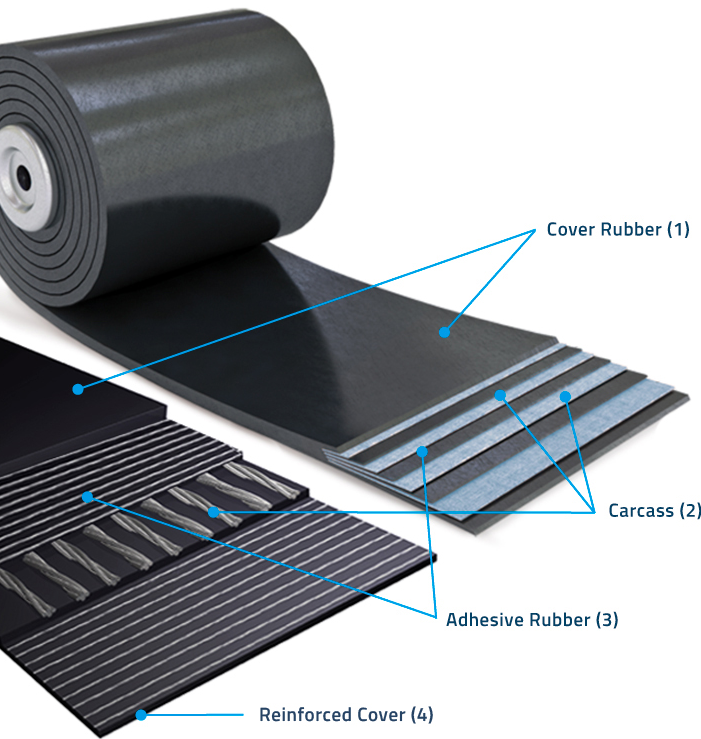

What is the structure of Rubber conveyor belt

Rubber conveyor belts are usually composed of the following layers: covering rubber (surface layer), skeleton material (reinforcement layer), bonding layer and edge protection

Covering rubber: It must have the characteristics of wear resistance, impact resistance, corrosion resistance, etc., and is divided into upper covering rubber (thicker) and lower covering rubber (thinner).

Skeleton material: including canvas layer (commonly used polyester, nylon, cotton fiber, etc., to provide tensile strength) and wire rope core (such as long-distance, large-volume transportation).

Adhesive layer: ensures the close bonding of rubber and skeleton material.

Edge protection: Some conveyor belts are designed with tear-resistant edges or sidewall structures.

How does the rubber conveyor belt work?

① Loading: The material is placed on the belt at the loading point, and the flow is usually controlled by a hopper or chute.

② Transport: The rubber conveyor belt transports the material along its path during movement.

③ Discharging: At the discharge end, the material is released by gravity (when the rubber conveyor belt bends around the tail pulley) or other equipment.

Features of rubber conveyor belt

Rubber conveyor belts use high-strength skeleton materials, high tensile strength, good wear resistance, and are suitable for long-distance and large-volume transportation.

Rubber conveyor belts can withstand high temperatures above 300°C, and can also be used in low-temperature environments of -50°C. The transportation of corrosive materials such as chemicals and fertilizers is also common.

Rubber conveyor belts are flame retardant and safe, and meet the safety standards of flammable and explosive places such as coal mines and tunnels. They are self-extinguishing and reduce the risk of fire.

Rubber conveyor belts can achieve closed conveying, prevent material spillage and environmental pollution, and are suitable for large-angle conveying.

Technical parameters of rubber conveyor belt

|

width |

Conveying length(m) power(kw) |

transfer speed (m/s) |

Delivery volume (t/h) |

||

|

400mm |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

30-60 |

|

500mm |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

40-80 |

|

650mm |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

80-120 |

|

800mm |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

120-200 |

|

1000mm |

≤10 |

10-20 |

20-40 |

1.25-2.0 |

200-320 |

|

1200mm |

≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 |

290-480 |

|

1400mm |

≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 |

400-680 |

|

1600mm |

≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 |

600-1080 |

|

1800mm |

≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 |

800-1500 |

|

2000mm |

≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 |

1000-2000 |

|

2400mm |

≤10 |

10-20 |

20-50 |

1.0-2.0 |

1500-3000 |

Applications of rubber conveyor belts

Rubber conveyor belts are very common in industries such as mining, manufacturing, agriculture and logistics. They can be customized for specific applications, such as heat resistance for high-temperature materials, oil resistance for greasy environments, and wear resistance for rough and heavy loads. Conveyor belts operate through pulleys and rollers in a conveying system driven by a motor, and are highly regarded for their efficient transportation of bulk materials such as coal, ore, grain or packaged goods.

Why do you need a rubber conveyor belt?

In the world of material handling and industrial processes, rubber conveyor belts play a vital role. These conveyors are designed to transport a variety of materials efficiently and reliably. Choosing the right rubber conveyor belt is essential to optimizing operations and ensuring a smooth workflow.

Rubber conveyor belt price

|

Model |

Belt width (mm) |

Length (m) |

Power (kw) |

Speed (m/s) |

Amount (t/h) |

Price (4/set) |

|

Horizontal sand conveyor belt |

B500 |

3 |

4-7.5 |

1.25-2.0 |

40-80 |

$2120-10750 |

|

Inclined sand conveyor belt |

B650 |

3 |

7.5-11 |

1.25-2.0 |

80-120 |

$4100-24230 |

|

Vertical sand conveyor belt |

B800 |

4 |

7.5-15 |

1.25-2.0 |

120-200 |

$5500-36300 |

|

Fixed sand conveyor belt |

B400 |

3 |

4-7.5 |

1.25-2.0 |

30-60 |

$2000-9430 |

|

Mobile sand conveyor belt |

B1000 |

5.5 |

7.5-22 |

1.25-2.0 |

200-320 |

$14800-249000 |

Supplier of Rubber conveyor belt

Choosing the right rubber conveyor belt is essential to optimizing operations in a variety of industries. By considering factors such as the type of transported material, the required capacity and throughput, environmental conditions, and cost, companies can choose a conveyor that meets their specific needs.

My whatsapp: +86 15236742901

e-mail: sale@xxdahan.com

You can contact Dahan Machinery's official customer service for more insights and guidance. By carefully evaluating different types of rubber conveyor belts and considering all relevant factors, companies can make smart investments that increase productivity, reduce costs, and improve overall operational efficiency.