In modern industrial production, material transportation is an indispensable link. In order to meet the needs of different industries for efficient and reliable transportation,

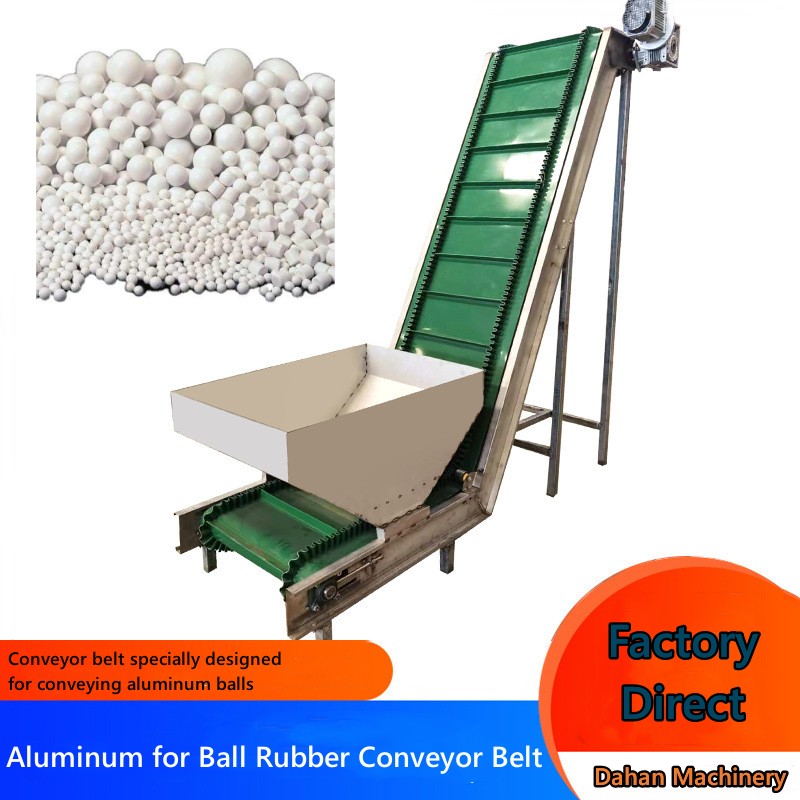

aluminum for ball rubber conveyor belts came into being. As an innovative rubber conveyor belt product, aluminum for ball rubber conveyor belt has become an ideal choice for all walks of life with its unique design and excellent performance.

High strength and wear resistance: Using special rubber material and aluminum alloy pellets, it has excellent wear resistance and high strength. It can operate stably for a long time under high load and harsh environment, reducing maintenance and replacement costs.

Excellent tensile properties: It has excellent tensile properties and can withstand the tensile force and impact load of heavy materials, ensuring the stability and safety of the conveying process.

Good temperature resistance: Aluminum for ball rubber conveyor belt can work in a wide temperature range, adapt to high and low temperature environments, maintain good mechanical properties and adhesion properties, and ensure the stability of material transportation.

Excellent adhesion performance: The aluminum alloy pellets on the surface provide good adhesion performance, which can effectively prevent material slipping and leakage, and improve conveying efficiency and safety.

Environmentally friendly and sustainable: Using environmentally friendly rubber materials and renewable aluminum alloy pellets, it has good weather resistance and anti-aging properties, extends service life, and reduces resource waste and environmental pollution.

Mining and metallurgical industry: Aluminum for ball rubber conveyor belt can withstand large particle materials and high temperature environments, and is used to transport ore, coal, slag and other materials to improve production efficiency and safety.

Building materials industry: aluminum for ball rubber conveyor belt is suitable for transporting cement, sand, bricks and other building materials to ensure the continuous operation of the production line and the even distribution of materials.

Grain processing industry: aluminum for ball rubber conveyor belt can be used to transport grain, feed and other materials to reduce material loss and cross-contamination, and improve production efficiency and food safety.

Packaging and logistics industry: Aluminum for ball rubber conveyor belt can withstand the transportation of heavy packaging materials and is used in warehousing and logistics systems to improve material transportation efficiency and reduce labor costs.

Place the aluminum ball on the conveyor belt and start the operation of the conveyor belt. The movement of the conveyor belt pushes the aluminum balls to the target position. The speed and tilt angle of the conveyor belt can be adjusted as needed to control the conveying speed and direction of the aluminum balls. Its high strength and wear resistance ensure stable transportation of aluminum balls while reducing maintenance and replacement costs.

In short, aluminum for ball rubber conveyor belt has become an ideal choice for material transportation in various industries due to its excellent performance and wide range of application fields. Whether in the mining, metallurgy, building materials or food processing and logistics industries, aluminum for ball rubber conveyor belt can provide efficient and reliable transportation solutions, helping companies improve production efficiency, reduce costs and ensure safety. When you choose aluminum for ball rubber conveyor belt, you will usher in a new and efficient transportation experience.