Truck loading conveyor is a device specially designed to load bulk goods (such as grain, powder, granules) or packaged goods (boxes, bags) from the ground or production line to the truck cargo hold quickly and efficiently. It can be fixed, mobile or telescopic, depending on actual needs. It is usually used in industries that require large amounts of material loading, handling and transportation, such as warehousing, logistics, construction, chemical industry, mining, etc.

①U-shaped trough screw conveyor pipeline (for truck loading)

Structure: Truck loading conveyors use trough screw conveyors, including U-shaped trough body, spiral blades, central shaft, drive motor, feed port and discharge port.

Working principle: The material enters the U-shaped trough through the feed port, and the screw rotates to push the material to the discharge port and unload it directly into the truck cargo compartment.

Features: Suitable for powdered or granular materials, with a conveying capacity of up to 134 m3/h.

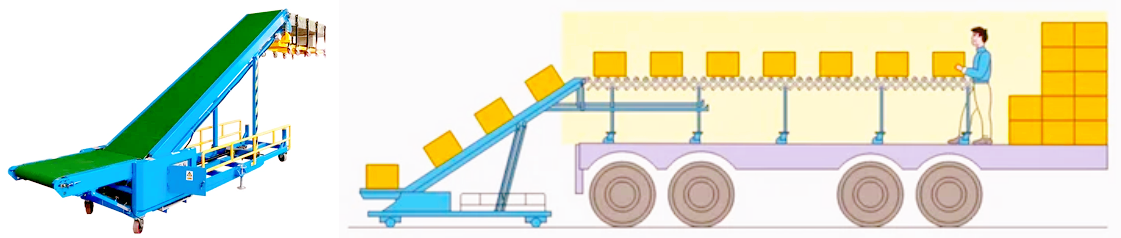

②Telescope Belt Conveyor

Structure: Truck loading conveyors are equipped with a retractable pipeline belt frame, rollers or traction devices, hydraulic lifting system and drive device.

Working principle: The pipeline belt extends into the interior of the truck, is transported to the designated location through freight, and retracts after completion.

Features: High flexibility, adjustable length and height, suitable for loading packaged goods (such as boxes, bags).

③Mobile Roller Conveyor

Structure: A portable frame composed of rollers or pulleys on a truck loading conveyor, which can be driven manually or electrically.

Working principle: Manual or push lifting materials move along rollers to the truck.

Features: Convenient, suitable for small or temporary loading tasks.

The main working principle of a truck loading conveyor is to transfer materials from the ground to the inside of a truck or container through the continuous operation of a spiral or belt conveyor belt. Its working process is as follows:

Feed port: Materials enter the truck loading conveyor from a production line, warehouse or other source through a silo or conveyor belt.

Transmission: Materials move along the conveyor through the conveyor belt or spiral system of the truck loading conveyor.

Loading: The conveyor belt or spiral belt transports the materials to the loading area of the truck, and adjusts the angle or speed of the conveyor through the control system so that the materials are evenly and quickly loaded into the truck cargo hold.

Materials will face many problems and challenges during transportation. Let's talk about how truck loading conveyors solve the problems.

① Solve uneven loading

The inventory is concentrated on the truck, resulting in unbalanced loading weight or low space utilization. Truck loading conveyors can use telescopic belt pipe machines that can extend into the truck and dynamically adjust the unloading position to ensure uniform distribution.

② Handle material loss or verification

Fragile inventory materials (such as grain) may deteriorate due to extrusion, or sensitive inventory (such as food raw materials) may deteriorate due to quality. The screw conveyor of the truck loading conveyor adjusts the speed (such as 20-50 RPM) to reduce mechanical damage to the unloading.

③ Prevent accumulation and poor flow

Sticky or wet terminals (such as wet grain, sticky powder) may block the pipeline channel and affect loading efficiency. Truck loading conveyors can use U-groove spiral pipe machines. Variable pitch screws or shaftless designs can be used to reduce unloading.

④ Avoid simultaneous flying and environmental pollution

Powdered inventory is prone to generate a lot of pollution during loading, polluting the environment and may cause health or safety hazards. The truck loading conveyor adopts a U-shaped trough spiral pipe machine, which can be equipped with a cover plate or a pipe structure to reduce overflow.

Logistics warehousing: Truck loading conveyor is used to transport goods from the inside of the warehouse to the truck for distribution. Whether it is small goods or large goods, the truck loading conveyor can complete the loading task quickly and accurately.

Mining: Truck loading conveyor is used to load the mined ore, coal and other materials onto the transport truck, which can adapt to the harsh working conditions and achieve efficient and stable material loading.

Construction: Truck loading conveyor is used to load construction materials such as sand and gravel onto the truck and transport them to the construction site. The conveying position and angle can be flexibly adjusted according to the layout of the construction site and the material requirements to ensure the timely supply of materials.

Port terminal: Truck loading conveyor is used to load goods from the yard onto the truck for transportation to other places. Ports have a wide variety of goods and a large flow rate. Truck loading conveyor can quickly and efficiently complete the loading operation of goods and ensure the smooth operation of port logistics.

Truck loading conveyor provides efficient, flexible and safe material loading solutions in multiple industries. It improves loading efficiency and reduces manual labor through automated control systems and adjustable designs. It is an indispensable equipment for material transportation in modern logistics, construction, chemical and other industries. If you have specific material transportation needs or need a customized solution, please provide more information and I can help you further analyze and select.