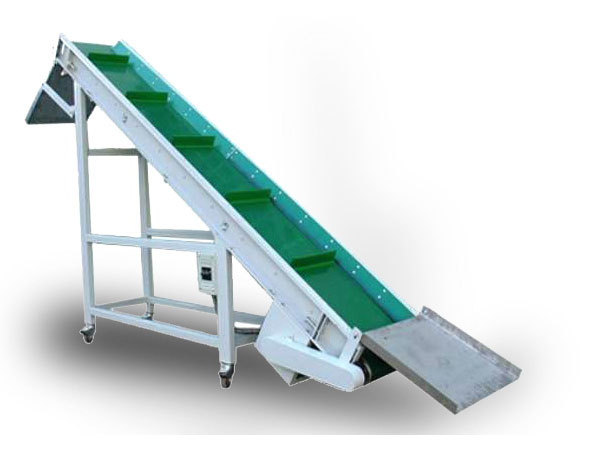

Corrosion Resistant Conveyor Belt

Corrosion-resistant conveyor belts are vital in industries handling corrosive materials like chemicals. They utilize materials such as stainless steel, PVC, or specialized coatings to withstand chemical exposure, ensuring prolonged equipment lifespan, safety, and efficiency. These belts prevent premature wear, reduce maintenance costs, and comply with industry regulations, making them essential for safe and effective material handling in challenging environments.

Corrosion-Resistant Conveyor Belts: Enhancing Material Handling in Challenging Environments

Significance of Corrosion Resistance

Corrosion-resistant conveyor belts play a crucial role in industries where materials such as acids, alkalis, salts, and other corrosive substances are transported. These belts are designed to withstand the damaging effects of chemical exposure, preventing premature wear and tear, and ensuring the safe and efficient handling of materials.

Materials for Corrosion Resistance

Stainless Steel: Known for its excellent corrosion resistance, stainless steel conveyor belts are a popular choice for handling corrosive materials. They are durable, easy to clean, and can withstand harsh environments.

Polyvinyl Chloride (PVC) and Polyurethane (PU): These materials are resistant to certain chemicals and acids, making them suitable for moderate corrosion resistance requirements.

Specialized Coatings: Some conveyor belts are coated with materials like Teflon or rubber to enhance their resistance to specific corrosive substances.

Benefits of Corrosion-Resistant Conveyor Belts

Extended Lifespan: Corrosion-resistant belts are designed to withstand chemical exposure, leading to longer equipment lifespan and reduced maintenance costs.

Improved Safety: By preventing belt degradation and potential failures, these belts enhance workplace safety and reduce the risk of accidents. Enhanced Efficiency: Smooth material flow and reduced downtime result in improved operational efficiency and productivity.

Compliance with Regulations: Corrosion-resistant conveyor belts meet industry standards for handling hazardous materials, ensuring regulatory compliance.

Corrosion Resistant Conveyor Belt Applications

Corrosion-resistant conveyor belts find applications in various industries, including:

Chemical Processing: Handling corrosive chemicals, acids, and alkalis.

Mining and Mineral Processing: Transporting ores and minerals in harsh environments.

Wastewater Treatment: Moving sludge, chemicals, and wastewater in treatment facilities.

Corrosion Resistant Conveyor Belt Applications

| Physical Property | ||

| Item | Before Aging | After Aging |

| Tensile Strength(Mpa) | 14 | 12 |

| Elongation At Break(%) | 400 | 340 |

| Abrasion(mm3) | 250 | ~ |

| Hardness,(o)+10-5 | 60 | 65 |

| Ozone Deterioration | No Cracks | ~ |

| Acid and Alkali Resistance | |||

| Class | A1 | A2 | A3 |

| Soak Liquid | HCL | H2SO4 | NaOH |

| Density | 18% | 50% | 48% |

| Soak Conditions (oCxh) | 50oC x 96h | 50oC x 96h | 50oC x 96h |

| Change Rate Before and After Soak,Swelling Rate | 0.1 | 0.1 | 0.1 |

| Change Rate Before and After Soak,Change Rate of Tensile Strength | -0.1 | -0.1 | -0.1 |

| The Whole Thickness | ||

| The Adhesive Strength of Rubber and Cloth | Cover > 1.5 mm | ≧ 3.2 N/mm |

| The Adhesive Strength of Rubber and Cloth( Longitudinal) | N | 3.2 N/mm |

| Elongation At Break ( Longitudinal) | ~ | ≧ 10% |

| Item | Tensile Strength /Mpa = | Elongation at break /% = | Abrasion /mm3 = | Hardness /(o)+10-5 | Ozone deterioration | ||

| Cover | Physical property | Before aging | 14 | 400 | 250 | 60 | No cracks |

| After aging | 12 | 340 | - | 65 | - | ||

| Acid and alkali resistance | Class | Soak liquid | Density | Soak conditions | Change rate before and after soak | ||

| oC x h | Swelling rate | Change rate of tensile strength | |||||

| A1 | HCL | 18% | 50oC x 96h | =+10% | =-10% | ||

| A2 | H2SO4 | 50% | 50oC x 96h | =+10% | =-10% | ||

| A3 | NaOH | 48% | 50oC x 96h | =+10% | =-10% | ||

Food Processing: Conveying acidic or alkaline food products safely.

Corrosion-resistant conveyor belts are indispensable in industries where materials pose a risk of equipment degradation and failure. By selecting the appropriate belt material, design, and maintenance practices, companies can ensure the safe and efficient handling of corrosive substances, enhance workplace safety, and optimize material handling processes in challenging environments. Investing in corrosion-resistant conveyor belts is a strategic decision that not only protects equipment but also improves overall operational performance and longevity in corrosive material handling applications.