Belt Conveyor for Pharmaceutical Industry

Belt Conveyor for Pharmaceutical Industry play a key role in meeting these requirements by providing reliable automated material handling solutions. Designed specifically for the pharmaceutical industry, these conveyors ensure safe and efficient transportation of raw materials, finished products, and packaging components throughout the production process.

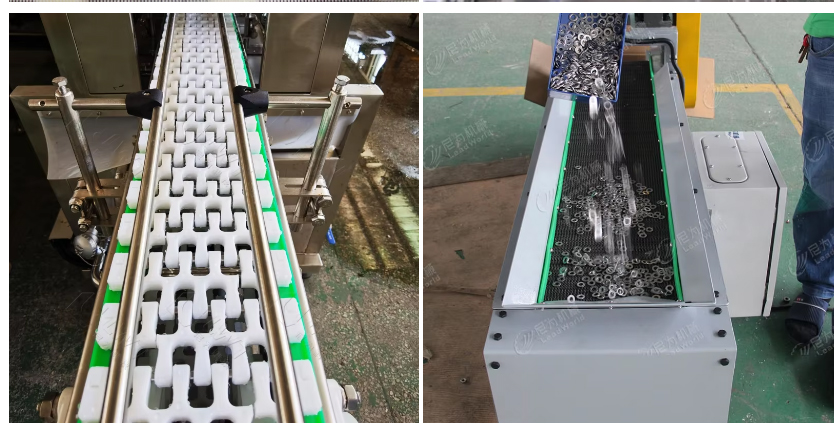

Belt Conveyor for Pharmaceutical Industry play a crucial role in the pharmaceutical industry by facilitating the efficient and safe transportation of materials within manufacturing facilities. These conveyors are designed to handle a wide range of pharmaceutical products, including tablets, capsules, vials, bottles, and other packaged goods.

Importance of Belt Conveyors in the Pharmaceutical Industry

Material Handling: Belt conveyors are essential for transporting raw materials, intermediate products, and finished goods between different stages of the pharmaceutical manufacturing process. They ensure smooth and continuous material flow, reducing the risk of contamination and product damage.

Automation and Efficiency: Belt conveyors help streamline production processes by automating material handling tasks. They increase operational efficiency, reduce manual labor requirements, and minimize the risk of human error in material transportation.

Cleanliness and Hygiene: In the pharmaceutical industry, maintaining high levels of cleanliness and hygiene is paramount. Belt conveyors designed for pharmaceutical applications are constructed using sanitary materials that are easy to clean and sanitize, ensuring compliance with strict industry regulations.

Product Protection: Belt conveyors with gentle handling capabilities are used to transport delicate pharmaceutical products without causing damage. They are equipped with features such as adjustable speed controls and soft-start mechanisms to prevent product breakage or spillage.

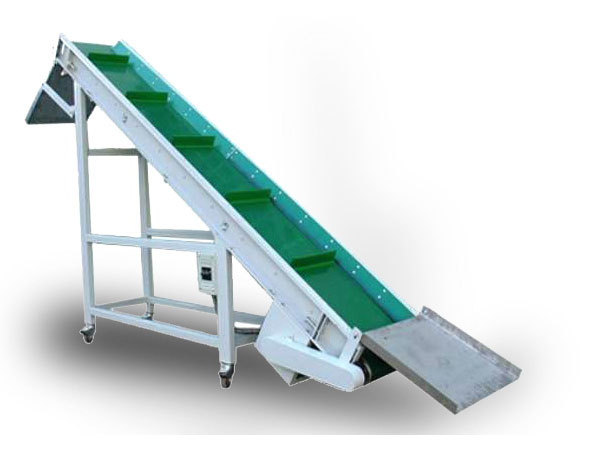

Versatility and Customization: Belt conveyors in the pharmaceutical industry can be customized to meet specific requirements, such as varying product sizes, weights, and shapes. They can be configured with different belt types, widths, lengths, and incline angles to suit diverse production needs.

Working Principle of Belt Conveyors

Belt: The conveyor belt is the primary component of a belt conveyor system. It consists of a continuous loop of material that rotates around two or more pulleys to transport goods from one end to the other.

Drive System: The belt is driven by a motorized pulley or drum, which provides the necessary power to move the belt and transport materials along the conveyor.

Support Structure: Belt conveyors are typically supported by a frame structure that includes idlers, rollers, and other components to maintain the alignment and tension of the conveyor belt.

Control System: Modern belt conveyors are equipped with advanced control systems that allow operators to adjust speed, direction, and other parameters to optimize material handling processes.

Benefits of Belt Conveyors in the Pharmaceutical Industry

Increased Productivity: Belt conveyors enable continuous material flow, reducing downtime and increasing overall production efficiency.

Cost-Effective: By automating material handling tasks, belt conveyors help reduce labor costs and improve operational profitability.

Safety: Belt conveyors are designed with safety features such as emergency stop buttons, guards, and sensors to prevent accidents and ensure worker safety.

Belt Conveyor for Pharmaceutical Industry are indispensable tools in the pharmaceutical industry, providing reliable and efficient material handling solutions that contribute to enhanced productivity, product quality, and regulatory compliance. By investing in high-quality belt conveyor systems tailored to pharmaceutical applications, manufacturers can streamline their operations, minimize risks, and maintain high standards of cleanliness and hygiene in their production processes.