Agricultural conveyor belt

Agricultural conveyor belts generally refer to conveying devices used to transport materials (such as grains, potatoes, fruits, fertilizers, etc.) in agricultural production.

Application: Commonly found in farms, grain processing plants, warehouses, greenhouses, etc.

Product Description

Agricultural conveyor belts are important equipment for conveying materials in agricultural production and processing. They are widely used in the handling, sorting, cleaning, and packaging of agricultural products such as grain, vegetables, fruits, and feed. Agricultural conveyor belts can convey a wide variety of materials, including various bulk materials, as well as various cartons, packaging bags, and other small-weight single-piece goods. Its design needs to adapt to the special needs of agricultural production, such as wear resistance, corrosion resistance, and easy cleaning, while meeting the conveying efficiency and cost requirements in different scenarios.

Types of agricultural conveyor belts

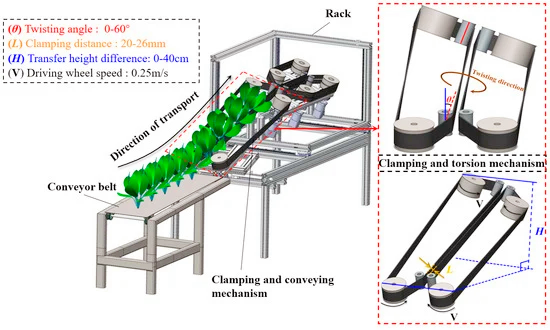

Agricultural conveyor belts are of various types according to their uses, structures, and application scenarios. They are specially designed for transporting grain, vegetables, seeds, feed, fertilizers, and other materials in agricultural production. Agricultural conveyor belts have various structural forms, including grooved belts, flat belts, climbing belts, tilting belts, turning belts, and other forms. Push plates, side baffles, skirts, and other accessories can also be added to the conveyor belts.

|

|

|

|

|

General purpose agricultural conveyor belts |

Food grade agricultural conveyor belts |

Sidewall agricultural conveyor belts |

|

|

|

|

|

Trough agricultural conveyor belt |

Curve belt agricultural conveyor belt |

Flat agricultural conveyor belt |

Applicable materials for agricultural conveyor belts

Agricultural conveyor belts are suitable for transporting a variety of agricultural-related materials, covering all links from planting to processing. The range of materials suitable for use varies depending on the physical characteristics of the material (such as shape, density, moisture) and the conveying requirements.

Bulk materials: Strong rubber belts (sometimes with V-shaped or carrier profiles) can effectively transport grain, fertilizer and other loose materials.

Inclined conveying: Agricultural conveyor belts with V-shaped profiles, cross-shaped profiles or sidewalls can handle steep angles up to 90 degrees.

Packaged goods: Agricultural conveyor belts with low friction coefficients are suitable for stacking items such as potted plants without tipping over.

Video of agricultural conveyor belts

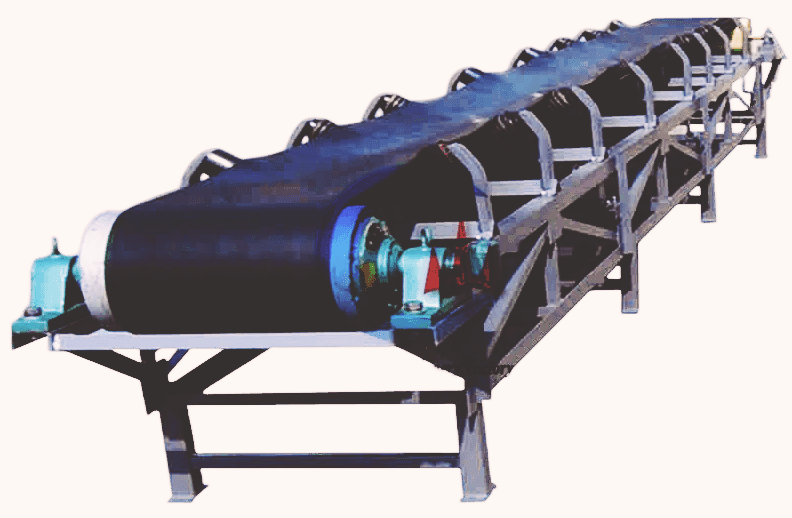

Structure of agricultural conveyor belts

Agricultural conveyor belts are mainly composed of frames, conveyor belts, belt rollers, tensioning devices, transmission devices, etc. The body is made of high-quality steel plates, and the frame is composed of the height difference between the front and rear legs, which is inclined at a certain angle to the plane. Belt rollers, rollers, etc. are installed on the frame to drive and support the conveyor belt. There are two ways: reduction motor drive and electric roller drive.

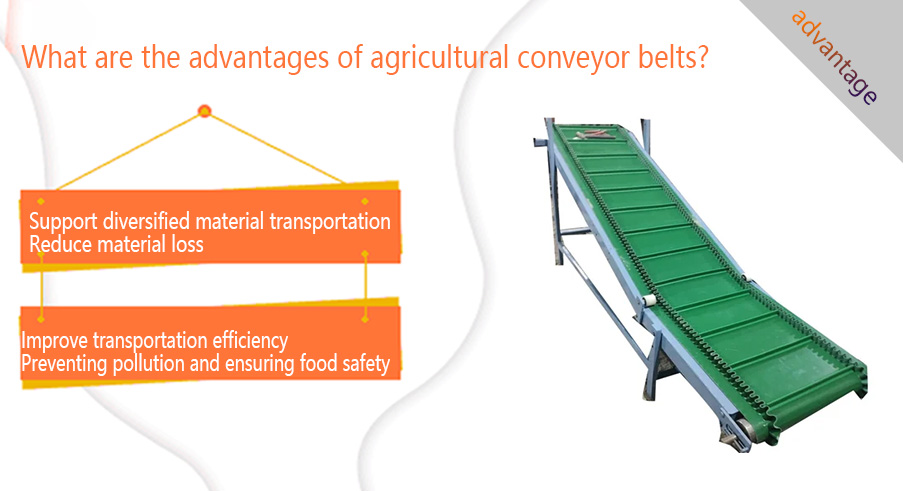

What are the advantages of agricultural conveyor belts?

In actual agricultural applications, materials do face many complex problems and challenges during transportation, such as loss, material spillage, blockage, corrosion, pollution, etc. In response to these problems, agricultural conveyor belt systems have been continuously optimized and upgraded.

Support diversified material transportation

Agricultural materials are of various types (such as granular grains, tuberous roots or fragile fruits and vegetables), and a single conveyor belt is difficult to meet the needs. Agricultural conveyor belts provide a variety of structures and surface designs, such as flat belts, corrugated sidewall belts or mesh belts, to adapt to different material characteristics.

Reduce material loss

Agricultural products (such as grains, fruits and vegetables, etc.) may be damaged or lost due to extrusion, impact or leakage during transportation. Agricultural conveyor belts use flexible materials (such as food-grade rubber or PVC) and smooth surface design to reduce mechanical damage to materials.

Improve transportation efficiency

Traditional transportation methods are inefficient, especially when handling large quantities or diversified agricultural products, which are prone to blockage or process interruption. Modern agricultural conveyor belts support automation and intelligent design, such as variable frequency speed regulation, which can adjust the speed according to the material flow to avoid overload or no-load operation.

Preventing pollution and ensuring food safety

During the transportation process, agricultural products may be contaminated by dust, chemical residues or bacteria, affecting food safety. Agricultural conveyor belts usually use materials that meet food safety standards, with easy-to-clean surfaces and strong antibacterial properties.

Key parameters of agricultural conveyor belts

|

Parameter category |

Typical options |

Applicable scenarios |

|

Belt width (mm) |

300/500/800/1200/1500 |

Select 300-500mm for small particles (seeds), and ≥1200mm for large bales (forage) |

|

Belt speed (m/s) |

0.1-0.5 (fruits and vegetables) / 1.0-2.5 (grain) |

Low speed for fragile materials, high speed for dry particles |

|

Material |

Rubber/PVC/PU/Nylon mesh/Stainless steel |

Rubber (wear-resistant), PU (sanitary), stainless steel (corrosion-resistant) |

|

Power (kW) |

1.5-30 (depending on length and load) |

About 3kW for a short distance of 10 meters, more than 15kW for a long distance of 50 meters |

|

Angle (°) |

0-20 (flat belt)/20-60 (edge belt) |

Baffles or partitions are required to prevent slipping when the angle exceeds 30° |

|

Temperature range (℃) |

-20~60 (conventional)/-40~120 |

Special materials are required for low temperature environments or drying lines |

Application of agricultural conveyor belts

Agricultural conveyor belts are widely used in the agricultural field, mainly in the feeding process of processed or frozen vegetables, fruits and other agricultural products for packaging and delivery to retailers or other processing plants. These agricultural conveyor belts can also be effectively used to load bulk goods onto trucks for transportation to their final destination. These agricultural conveyor belts are designed to meet the needs of agricultural industry applications, such as animal feed, tobacco, grapes, sugar, fertilizers and grains.

Typical cases of agricultural conveyor belts

Large feed mills: use high-strength rubber agricultural conveyor belts to realize the automated transportation of raw materials from storage to processing workshops, and increase production efficiency by 40%.

A fruit and vegetable sorting center: using PVC patterned agricultural conveyor belts, combined with intelligent sorting equipment, the sorting accuracy rate is over 98%.

Corn planting cooperatives: equipping corn harvesters with special agricultural conveyor belts, increasing the daily harvest by 3 times and reducing labor costs by 60%.

Customer Cases of Agricultural Conveyor Belts

|

|

|

|

|

Olive oil agricultural conveyor belt |

Grape cultivation agricultural conveyor belt |

Fruit agricultural conveyor belt |

|

|

|

|

|

Refined sugar agricultural conveyor belt |

Tobacco agricultural conveyor belt |

Fruit and vegetable agricultural conveyor belt |

|

|

|

|

|

Tea agricultural conveyor belt |

Greenhouse plant agricultural conveyor belt |

Oatmeal bucket elevator |

Manufacturer of Agricultural Conveyor Belts

Xinxiang Dahan Vibration Machinery Co., Ltd. is a company specializing in the research and development and manufacturing of agricultural conveying equipment. It provides various types of agricultural conveyor belts and complete conveying systems, which are widely used in the transportation of materials such as grain, fruits and vegetables, feed, and fertilizer.

When choosing an agricultural conveyor belt, the following factors should be considered:

Material type: such as grain, fruits and vegetables, feed, fertilizer, etc.

Conveying method: horizontal, inclined or vertical conveying.

Conveying environment: indoor or outdoor, whether it needs to be moved.

Conveying volume and distance: select the appropriate conveying equipment according to actual needs.

For more product information or customized solutions, it is recommended to visit the official website of Dahan Machinery or contact our manufacturer directly for detailed information.